I-Monel Alloy 400

Inkcazelo emfutshane:

IMonel 400yii-nickel-copper alloy(malunga ne-67% ye-Ni - 23% Cu) ekwaziyo ukumelana namanzi olwandle kunye nomphunga kumaqondo obushushu aphezulu kunye netyuwa kunye nezisombululo ze-caustic.Ingxubevange 400sisisombululo esiqinileyo esinokuthi siqiniswe kuphela ngokusebenza okubandayo. Le nickel alloy ibonisa iimpawu ezifana nokuxhathisa okulungileyo kokutya, ukuwelda okulungileyo kunye namandla aphezulu. Izinga eliphantsi lokutya emanzini amdaka aqukuqelayo okanye amanzi olwandle adityaniswe nokuxhathisa okugqwesileyo kuxinzelelo-ukuqhekeka kwe-corrosion kumanzi amaninzi acocekileyo, kunye nokuchasana kwayo neemeko ezinobungozi eziye zakhokelela ekusetyenzisweni kwayo ngokubanzi kwizicelo zaselwandle kunye nezinye izisombululo zekloridi ezingena-oxidizing. Le nickel alloy ixhathisa ngokukodwa kwi-hydrochloric kunye ne-hydrofluoric acids xa i-de-aerated. Njengoko kuya kulindeleka kumxholo wayo ophezulu wobhedu, i-alloy 400 ihlaselwa ngokukhawuleza yi-nitric acid kunye neenkqubo ze-ammonia.

I-Monel 400 ineepropati ezinkulu zoomatshini kumaqondo obushushu angaphantsi kwe-subzero, ingasetyenziswa kumaqondo obushushu ukuya kuthi ga kwi-1000 ° F, kwaye indawo yayo yokunyibilika yi-2370-2460 ° F. Nangona kunjalo, i-alloy 400 iphantsi ngamandla kwimeko edibeneyo ngoko, iintlobo ezahlukeneyo zomsindo. ingasetyenziselwa ukwandisa amandla.

Iifom ziyafumaneka

- Iphepha

- Ipleyiti

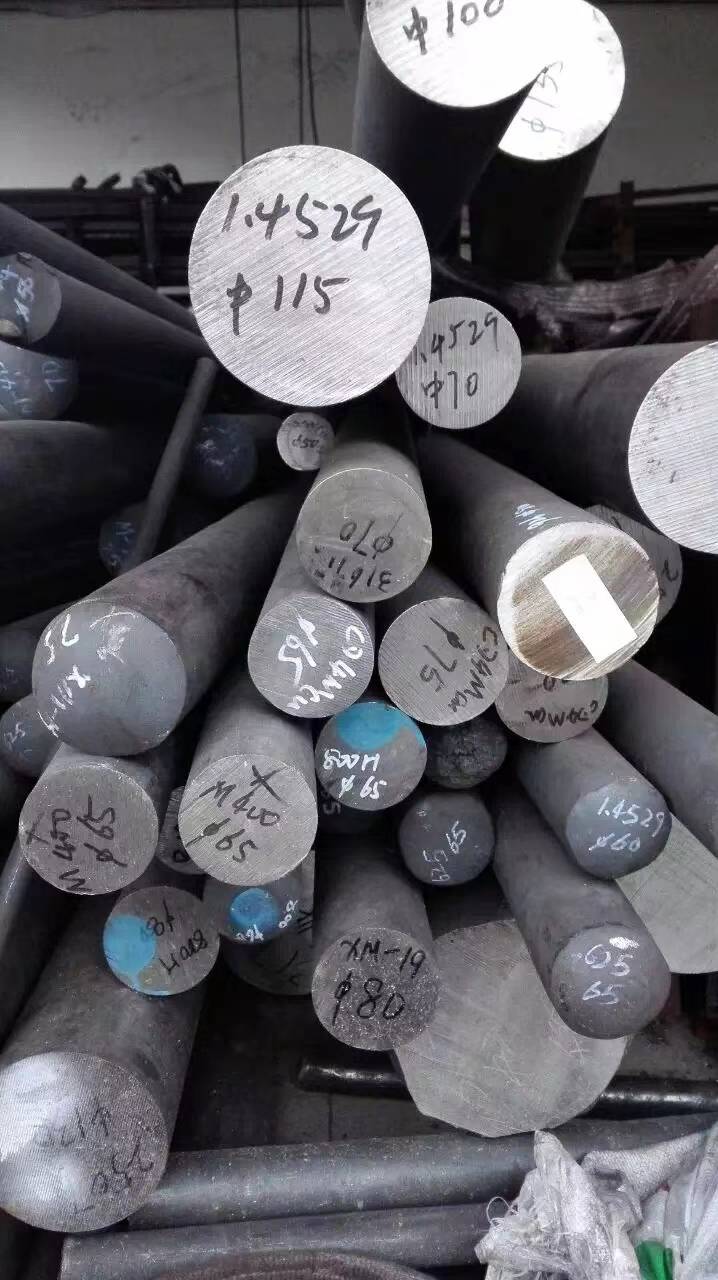

- Ibha

- Umbhobho & Umbhobho (welding & engenamthungo)

- Izinto zokufakela (okt, iiflange, ii-slip-ons, iiblinds, i-weld-necks, i-lapjoints, ii-welding iintamo ezinde, ii-socket welds, i-elbows, ii-tee, ii-stub-ends, ii-returns, iikepusi, iminqamlezo, izinciphisa, kunye neengono zemibhobho)

- Ucingo

Ziziphi iimpawu zeMonel 400?

- Ukumelana namanzi olwandle kunye nomphunga kumaqondo obushushu aphezulu

- Ukumelana okugqwesileyo kumanzi amdaka aqukuqelayo okanye amanzi olwandle

- Ukuchasana okugqwesileyo kuxinzelelo lwe-corrosion cracking kuninzi lwamanzi acocekileyo

- Ngokukodwa ukumelana ne-hydrochloric kunye ne-hydrofluoric acids xa i-de-aerated

- Inika ukuxhathisa okuthile kwi-hydrochloric kunye ne-sulfuric acid kumaqondo aphantsi kunye nokugxila, kodwa ayifane ibe yinto ekhethwayo kwezi asidi.

- Ukuchasana okugqwesileyo kwityuwa engathathi hlangothi kunye ne-alkaline

- Ukuchasana nekloridi kubangele uxinzelelo lwe-corrosion cracking

- Iimpawu ezilungileyo zoomatshini ukusuka kumaqondo obushushu angaphantsi kwe-zero ukuya kuthi ga kwi-1020° F

- Ukuchasana okuphezulu kwi-alkalis

Ukuqulunqwa kwemichiza, %

| C | Mn | S | Si | Ni | Cu | Fe |

|---|---|---|---|---|---|---|

| .30 ubuninzi | 2.00 ubuninzi | .024 ubuninzi | .50 ubuninzi | 63.0 imiz | 28.0-34.0 | 2.50 ubuninzi |

I-Monel 400 enganyangekiyo kwi-Corrosion

Ingxubevange 400ikhuselekile kwikloride ion stress corrosion cracking kwiindawo eziqhelekileyo. Ngokuqhelekileyo, ukuxhathisa kwayo ku-corrosion kuhle kakhulu ekunciphiseni okusingqongileyo, kodwa ihlwempu kwiimeko ze-oxidizing. Ayiloncedo kwi-acids oxidizing, njenge-nitric acid kunye ne-nitrous. Nangona kunjalo, iyaxhathisa kwii-alkalis ezininzi, iityuwa, amanzi, iimveliso zokutya, izinto eziphilayo kunye neemeko ze-atmospheric kumaqondo obushushu aqhelekileyo kunye aphakamileyo.

Le nickel alloy ihlaselwa kwiigesi ezithwala isulfure ngaphezulu kwe-700 ° F kwaye isulfure etyhidiweyo ihlasela ialloy kumaqondo obushushu angaphezulu kwama-500 ° F.

I-Monel 400 inikezela malunga nokuxhathisa okufanayo kwe-corrosion njenge-nickel kodwa kunye noxinzelelo oluphezulu lokusebenza kunye namaqondo okushisa kunye nexabiso eliphantsi ngenxa yobuchule bayo obuphezulu bomatshini.

Kweziphi izicelo iMonel 400 isetyenziswa?

- Ubunjineli baselwandle

- Izixhobo zokulungisa iikhemikhali kunye ne-hydrocarbon

- Ipetroli kunye neetanki zamanzi acocekileyo

- Imizobo yepetroleum ekrwada

- Izifudumezi ezikhupha umoya

- Izifudumezi zamanzi ze-boiler kunye nezinye izifudumezi zobushushu

- Iivalvu, iimpompo, iishafti, izifakelo, kunye neziqhoboshi

- Abatshintshi bobushushu boshishino

- Izinyibilikisi ezineklorini

- Iinqaba zokulahla ioli ekrwada

Ukwenziwa kweMonel 400

I-alloy 400 inokudityaniswa ngokulula nge-gas-tungsten arc, i-arc yensimbi yegesi okanye iinkqubo ze-arc zentsimbi ezikhuselweyo zisebenzisa iintsimbi ezifanelekileyo zokuzalisa. Akukho mfuneko yonyango lwe-weld heat heat, nangona kunjalo, ukucocwa ngokucokisekileyo emva kwe-welding kubaluleke kakhulu ekuxhathiseni ukubola, ngaphandle koko kukho umngcipheko wokusuleleka kunye nokuxhamla.

Iimveliso ezigqityiweyo zinokuveliswa kuluhlu olubanzi lweempawu zomatshini xa ulawulo olufanelekileyo lobungakanani bomsebenzi oshushu okanye obandayo kunye nokukhethwa konyango olufanelekileyo lwe-thermal lwenziwa.

Njengazo zonke ezinye iialloyi zenickel, iMonel 400 idla ngokuba nzima kumatshini kwaye iya kusebenza nzima. Nangona kunjalo, iziphumo ezigqwesileyo zinokufunyanwa ukuba wenza ukhetho oluchanekileyo lwezixhobo kunye nomatshini.

IBanga leMathiriyeli

| Izinto eziphathekayo | Umgangatho we-ASTM A240 | 201, 304 304L 304H 309S 309H 310S 310H 316 316H 316L 316Ti 317 317L 321 321H 347 347H 409 410 40009 |

| Umgangatho we-ASTM A480 | 302, s30215, s30452, s30615, 308, 309, 309Cb, 310, 310Cb, S32615, S33228, S38100, 304H, 309H, 316H3H 310, 310H 310, 310H 310, 310H 3H 347H, 348H, S31060, N08811, N08020, N08367, N08810, N08904,N08926, S31277, S20161, S30600, S30601, S31254, S31266,S32050, S32654, S32053, S31727, S30601, S335161 03, S32001, S32550, S31260, S32003, S32101,S32205, S32304, S32506, S32520, S32750, S32760, S32900, S32906, S32950, S32974 | |

| I-JIS 4304-2005 Standard | SUS301L,SUS301J1,SUS302,SUS304, SUS304L, SUS316/316L, SUS309S, SUS310S, 3SUS21L, SUS347, SUS410L, SUS430, SUS630 | |

| Umgangatho we-JIS G4305 | SUS301, SUS301L, SUS301J1, SUS302B, SUS304, SUS304Cu,SUS304L, SUS304N1, SUS304N2, SUS304LN, SUS304J1, SUSJ2,SUS305, SUS304S, SUS301S 15J2,SUS316, SUS316L, SUS316N, SUS316LN, SUS316Ti, SUS316J1,SUS316J1L, SUS317, SUS317L, SUS317LN, SUS317J1, SUS317J2,SUS836L, SUS890L, SUS321, SUS347, SUSXM7, SUSXM15J1, SUS329J3US44, SUS329JS4, SUS347 SUS430, SUS430LX, SUS430J1L, SUS434, SUS436L, SUS436J1L, SUS444, SUS445J1, SUS445J2, SUS447J1, SUSXM27, SUS403,SUS410, SUS410S, SUS420J1, SUS420J2, SUS440A |

Ukucaciswa kweMveliso

| Gqiba | Ukutyeba | Iimpawu | Usetyenziso |

| Inombolo 1 | 3.0mm~50.0mm | Igqitywe ngokushushumbisa, i-annealing kunye ne-pickling, ebonakaliswe ngumphezulu omhlophe ocoliweyo | Izixhobo zeshishini lemichiza, iitanki zeShishini |

| No. 2B | 0.3mm ~ 6.0mm | Kugqitywe unyango ubushushu, pickling emva ebandayo rolling, kulandele ulusu pass line ukuba liqaqambe ngakumbi kwaye agudileyo ubuso | Izixhobo zezoNyango eziSebenzisiweyo, iTableware |

| INombolo ye-BA (Eqaqambileyo eAnealed) | 0.5mm ~ 2.0mm | Ukunyangwa kobushushu obuqaqambileyo emva kokuqengqeleka okubandayo | Ikhitshi yekhitshi, ikhitshi, injongo yezakhiwo |

| Inombolo yesi-4 | 0.4mm ~ 3.0mm | Ukucoca ngeNombolo ye-150 ukuya kwi-No.180 ye-mesh abrasives. Ukugqiba okudumileyo | Amaziko okwenziwa kobisi kunye nokutya, izixhobo zesibhedlele, ibhafu |

| Inombolo yesi-8 | 0.5mm ~ 2.0mm | Umphezulu onjengesipili obonakalisayo ngokugudiswa ngezithinteli ezicolekileyo ngaphezu kwe-800 mesh | IReflector, isipili, Ngaphakathi-Uhombiso lwangaphandle lolwakhiwo |

| HL(Umgca weNwele) | 0.4mm ~ 3.0mm | Igqitywe ngokucolwa ngokuqhubekayo komgca | Iinjongo zezakhiwo, izitepusi ezizihambelayo, izithuthi zasekhitshini |

Ukuqulunqwa kwemichiza

| IBanga | C | Si | Mn | P | S | Cr | Ni | Mo | Ti | N | Cu | Nb |

| 201 | ≤0.15 | ≤1.0 | 5.50-7.50 | ≤0.05 | ≤0.03 | 16.00-18.00 | 3.50-5.50 | - | - | 0.05-0.25 | - | - |

| 202 | ≤0.15 | ≤1.0 | 7.50-10.00 | ≤0.05 | ≤0.03 | 17.00-19.00 | 4.00-6.00 | - | - | 0.05-0.25 | - | - |

| 301 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 16.00-18.00 | 6.00-8.00 | - | - | ≤0.1 | - | - |

| 302 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 17.00-19.00 | 8.00-10.00 | - | - | ≤0.1 | - | - |

| 303 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.2 | ≥0.15 | 17.00-19.00 | 8.00-10.00 | ≤0.6 | - | ≤0.1 | - | - |

| 304 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 17.00-19.00 | 8.00-10.00 | - | - | - | - | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 18.00-20.00 | 8.00-10.00 | - | - | - | - | - |

| 304H | 0.04-0.1 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 18.00-20.00 | 8.00-10.00 | - | - | - | - | - |

| 304N | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 18.00-20.00 | 8.00-10.00 | - | - | 0.10-0.16 | - | - |

| 304J1 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 18.00-20.00 | 6.00-9.00 | - | - | - | 1.00-3.00 | - |

| 305 | ≤0.12 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 17.00-19.00 | 10.50-13.00 | - | - | - | - | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 22.00-24.00 | 12.00-15.00 | - | - | - | - | - |

| 310S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 24.00-26.00 | 19.00-22.00 | - | - | - | - | - |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | - | - | - | - |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | 12.00-15.00 | 2.00-3.00 | - | - | - | - |

| 316H | ≤0.1 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | - | - | - | - |

| 316N | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | - | 0.10-0.16 | - | - |

| 316Ti | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 16.00-19.00 | 11.00-14.00 | 2.00-3.00 | ≥5C | - | - | - |

| 317L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | 3.00-4.00 | - | - | - | - |

| 321 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 17.00-19.00 | 9.00-12.00 | - | 5C-0.7 | - | - | - |

| 347 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 17.00-19.00 | 9.00-12.00 | - | - | - | - | 10C-1.10 |

| 347H | ≤0.1 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 17.00-19.00 | 9.00-12.00 | - | - | - | - | 8C-1.10 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 21.00-24.00 | 4.50-6.50 | 2.50-3.50 | - | 0.08-0.20 | - | - |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 24.00-26.00 | 6.00-8.00 | 3.00-5.00 | - | 0.24-0.32 | - | - |

| 904L | ≤0.02 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 19.00-23.00 | 23.00-28.00 | 4.00-5.00 | - | - | 1.00-2.00 | - |

| C276 | ≤0.02 | ≤0.05 | ≤1.0 | - | - | 14.00-16.50 | Okunye | - | - | - | - | - |

| Monel400 | ≤0.3 | ≤0.5 | ≤2.0 | - | ≤0.024 | - | ≥63 | - | - | - | 28-34 | - |

| 409L | ≤0.03 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 17.00-19.00 | - | - | - | - | - | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 11.50-13.50 | - | - | - | - | - | - |

| 410L | ≤0.03 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 11.50-13.50 | - | - | - | - | - | - |

| 420J1 | 0.16-0.25 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 12.00-14.00 | - | - | - | - | - | - |

| 420J2 | 0.26-0.40 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 12.00-14.00 | - | - | - | - | - | - |

| 430 | ≤0.12 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | - | - | - | - | - | - |

| 436L | ≤0.025 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 16.00-19.00 | - | - | - | - | - | - |

| 439 | ≤0.03 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | - | - | - | - | - | - |

| 440A | 0.60-0.75 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | - | ≤0.75 | - | - | - | - |

| 440B | 0.75-0.95 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | - | ≤0.75 | - | - | - | - |

| 440C | 0.95-1.2 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | - | ≤0.75 | - | - | - | - |

| 441 | ≤0.03 | 0.2-0.8 | ≤0.7 | ≤0.03 | ≤0.015 | 17.50-18.50 | - | ≤0.5 | 0.1-0.5 | ≤0.025 | - | 0.3+3C-0.9 |

Thinazisonga iimveliso zensimbi ezingenasici ngephepha elichasayo kunye nentsimbi yentsimbi ukukhusela umonakalo.

Iileyibhile zokuchongwa ziphawulwe ngokwemigaqo esemgangathweni okanye ngokwemiyalelo yomthengi.

Ukupakishwa okukhethekileyo kuyafumaneka ngokwemfuno yomthengi.

Ipakethe yekhoyili yensimbi engenaStainless

Iphepha leNsimbi elingenaStainless / iPakeji yePleyiti yentsimbi engatyiwa

Ipakethe yeStrip Strip

Ipakethe yokuThunyelwa

Inkampani yethu izinze eWuxi, iqokelela isixeko sesinyithi esingenasici eTshayina.

Sisebenza ngokukhethekileyo kwiikhoyili ezingenasici, amashiti kunye nepleyiti, umbhobho wentsimbi engatyiwa kunye nezinto zokufakelwa, iityhubhu zentsimbi, kunye neemveliso ze-aluminiyam kunye neemveliso zobhedu.

Iimveliso zethu ziye zanconywa kakhulu ngabathengi bethu abavela eYurophu, eMelika, kuMbindi Mpuma, eAfrika nakuMzantsi-mpuma Asia. Siza kubonelela ngeemveliso ezikhuphisanayo kunye nenkonzo ebanzi kubathengi.

IBanga leStainless Steel: 201, 202, 202cu, 204, 204cu, 303, 304, 304L, 308, 308L, 309, 309s, 310, 310s, 316, 316, 4, 4, 4, 4, 4, 4 0, 430F, 440, 440c,

IBanga le-alloy: iMonel, i-Inconel, iHastolley, iDuplex, iSuper Duplex, iTitanium, iTantalum, iSpeed Speed Steel, intsimbi eMild, iAluminium, iAlloy Steel, Carbon Steel, Special Nickel Alloys

Kwimo ye: IiBar eziRound, iiBar zesikwere, ii-Hexagonal Bars, ii-Flat Bars, ii-engile, ii-Channels, iiProfayili, iiNcingo, iiNcingo zocingo, ii-Sheets, iiPleti, iMibhobho engenamthungo, i-ERW Pipes, iiFlanges, iiFittings, njl.

Q1: Yintoni i-stainless?

A: I-stainless ithetha ukuba akukho manqaku kumphezulu wentsimbi, okanye uhlobo lwentsimbi engonakaliswanga ngumoya okanye ngamanzi kwaye engatshintshi umbala, engenabala, ekwazi ukumelana nokubola, ukurusa, isiphumo sokubola kweekhemikhali.

I-Q2: Ngaba i-stainless ithetha ukuba akukho ukugqwala?

IMPENDULO: Hayi, i-stainless ithetha ukuba akukho lula ukungcola okanye ukurusa, inamandla akhethekileyo okuxhathisa ibala, ukurusa kunye nokuhlwa.

I-Q3: Ngaba unikezela ngamashiti ensimbi engenasici?

A: Ewe, sinikezela ngeentlobo ezahlukeneyo zeshiti zensimbi ezingenasici, ezinobubanzi obusuka kwi-0.3-3.0mm. kunye nokugqiba ezahlukeneyo.

I-Q4: Ngaba uyayamkela inkonzo yokusika ukuya kubude?

A: Ewe, ukwaneliseka kwabathengi yeyona nto iphambili kuthi.

Q5: Ukuba ndineodolo encinci, uyayamkela iodolo encinci?

A: Akuyongxaki, inkxalabo yakho yinkxalabo yethu, amanani amancinci amkelwe.

I-Q6: Ungaqinisekisa njani umgangatho wemveliso yakho?

A: Okokuqala, kwasekuqaleni, sele siphumeze umoya ezingqondweni zabo, obo bubomi obusemgangathweni, abasebenzi bethu abaqeqeshiweyo kunye nabasebenzi baya kulandela inyathelo ngalinye de iimpahla zipakishwe kakuhle kwaye zithunyelwe ngaphandle.

I-Q7: Ngaba uya kupakisha iimveliso?

A: Abantu abachwephesha benza ukupakisha abaqeqeshiweyo, sineentlobo ezahlukeneyo zokupakisha ozikhethelayo kubathengi, uqoqosho okanye olungcono.

I-Q8: Yintoni ekufuneka uyazi kumthengi ngaphambi kokucaphula okuchanekileyo?

A: Ukufumana ikowuteshini echanekileyo, kufuneka sazi ibakala, ubukhulu, ubukhulu, ukugqiba komphezulu, umbala kunye nobungakanani beodolo yakho, kunye nendawo eziya kuyo iimpahla. Ulwazi lwemveliso elungiselelweyo luya kufuneka ngakumbi, njengokuzoba, uyilo kunye nesicwangciso. Emva koko siya kubonelela ngekowuteshini ekhuphisanayo kunye nolwazi olungentla.

I-Q9: Loluphi uhlobo lwexesha lokuhlawula olivumayo?

A: Siyayamkela i-T/T, i-West union, i-L/C.

I-Q10: Ukuba lo ngumyalelo omncinci, ngaba uya kuhambisa iimpahla kwi-arhente yethu?

A: Ewe, sizalelwe ukusombulula iingxaki zabathengi bethu, siya kufumana iimpahla ngokukhuselekileyo kwindawo yokugcina iarhente yakho kwaye sikuthumelele imifanekiso.

Q11: Ngaba wenza ishiti elicaba? Ndifuna ukwenza ulwakhiwo lweprojekthi yam entsha.

A: Hayi, sivelisa ubukhulu becala isinyithi esingenasici esisicaba sonyango, kwangaxeshanye, senza imveliso egqityiweyo yentsimbi egqityiweyo ngokomzobo kunye nesicwangciso somthengi, igcisa lethu liya kukhathalela abanye.

Q12: Zingaphi iicoutries osele uzithumele ngaphandle?

A: Ithunyelwa kumazwe angaphezu kwama-50 ikakhulu isuka eMelika, eRashiya, eUK, eKuwait, eYiphutha, eIran,

Turkey, Jordan, njl.

Q13: Ndingazifumana njani iisampuli?

A: Iisampuli ezincinci kwivenkile kwaye zinokubonelela ngeesampuli simahla. I-Catalgue iyafumaneka, uninzi

iipatheni esinazo iisampulu esele zilungile kwisitokhwe. Iisampuli ezenziwe ngokwezifiso ziya kuthatha malunga ne-5-7days.

Q14: Yintoni ukuhanjiswa?

A: Ixesha lokuhanjiswa kwesampula yi-5- 7 iintsuku. Iiodolo zesikhongozeli malunga neentsuku ze-15-20.

Q15: Sithini isicelo malunga neeMveliso zakho?

A: Umnyango we-elevator / i-cabin okanye kunye nodonga olusecaleni lwe-escalator.

2.Izigqubuthelo zodonga ngaphakathi okanye ngaphandle kwegumbi lentlanganiso/ indawo yokutyela.

3.I-Facade xa ugqume phezu kwento ethile, njengeekholamu kwindawo yokwamkela iindwendwe.

4.Isilingi kwivenkile enkulu. 5.Decorative umzobo kwezinye iindawo zokuzonwabisa.

I-Q16: Ungayiqinisekisa ixesha elingakanani le Mveliso / ukugqiba?

A: Isiqinisekiso sombala ngaphezu kweminyaka eyi-10. Isiqinisekiso somgangatho wemathiriyeli yoqobo sinakho

kubonelelwa.