Monel Alloy 400

Katerangan pondok:

Monel 400nyaeta aalloy nikel-tambaga(kira-kira 67% Ni - 23% Cu) anu tahan ka cai laut sareng uap dina suhu anu luhur ogé pikeun larutan uyah sareng caustic.Paduan 400mangrupakeun alloy solusi padet nu ngan bisa hardened ku kerja tiis. alloy nikel Ieu némbongkeun ciri kawas lalawanan korosi alus, weldability alus sarta kakuatan tinggi. Laju korosi anu rendah dina cai payau atanapi laut anu ngalir gancang digabungkeun sareng résistansi anu saé pikeun retakan stres-korosi di kalolobaan cai tawar, sareng résistansina kana rupa-rupa kaayaan korosif nyababkeun panggunaan anu lega dina aplikasi laut sareng solusi klorida non-oksidasi anu sanés. alloy nikel ieu utamana tahan ka asam hidroklorat jeung hidrofluorat nalika aranjeunna de-aerated. Sapertos anu dipiharep tina eusi tambaga anu luhur, alloy 400 gancang diserang ku asam nitrat sareng sistem amonia.

Monel 400 boga sipat mékanis hébat dina suhu subzero, bisa dipaké dina hawa nepi ka 1000 ° F, sarta titik lebur nyaeta 2370-2460 ° F. Sanajan kitu, alloy 400 low kakuatan dina kaayaan annealed jadi, rupa-rupa tempers. bisa dipaké pikeun ngaronjatkeun kakuatan.

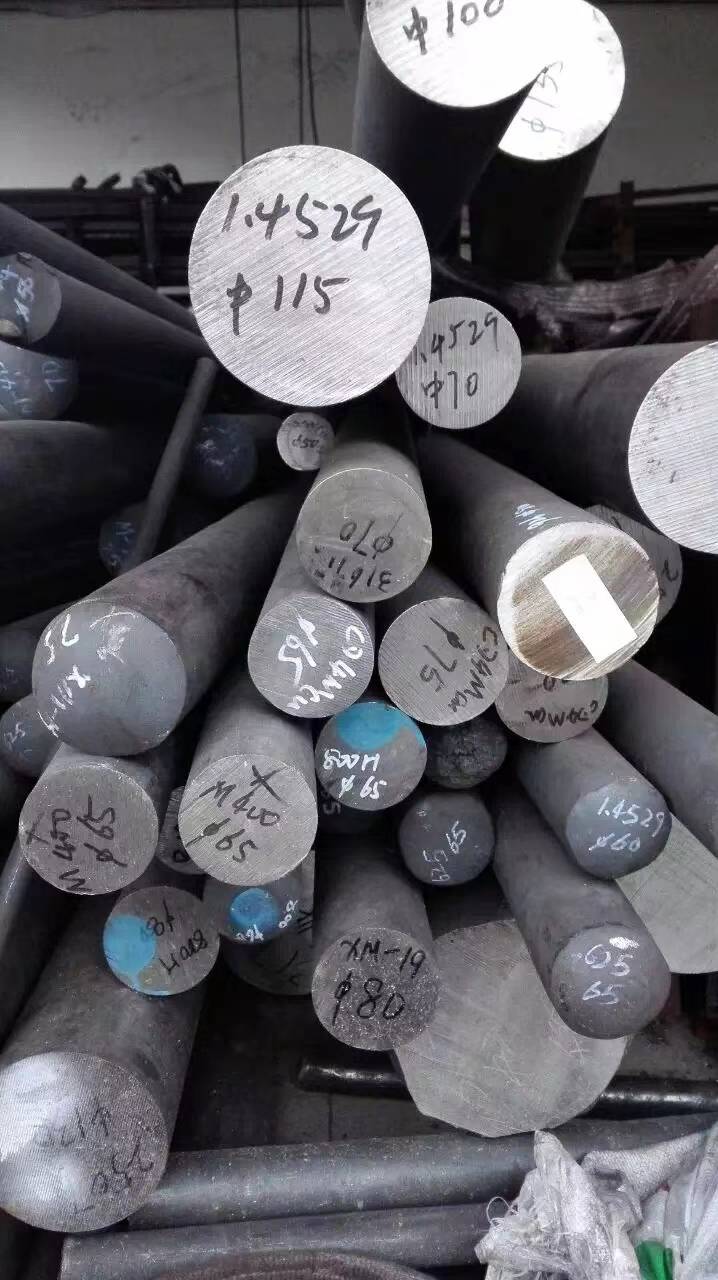

Bentuk sadia

- Lambaran

- Piring

- Bar

- Pipa & Tube (dilas & mulus)

- Fittings (ie flanges, slip-ons, blinds, weld-beuheung, lapjoints, beuheung las panjang, welds stop kontak, elbows, tees, rintisan-tungtung, mulang, caps, crosses, reducer, sarta nipples pipa)

- Kawat

Naon ciri Monel 400?

- Tahan ka cai laut sareng uap dina suhu anu luhur

- Résistansi anu saé pikeun cai payau atanapi cai laut anu ngalir gancang

- Résistansi anu saé pikeun retakan korosi stres dina kalolobaan cai tawar

- Utamana tahan ka asam hidroklorat sareng hidrofluorat nalika aranjeunna de-aerasi

- Nawarkeun sababaraha résistansi kana asam hidroklorat sareng sulfat dina suhu sareng konsentrasi anu sederhana, tapi jarang janten bahan pilihan pikeun asam ieu.

- Résistansi anu saé pikeun uyah nétral sareng basa

- Résistansi ka klorida ngainduksi stress korosi cracking

- Sipat mékanis anu saé tina suhu sub-enol dugi ka 1020 ° F

- Résistansi luhur pikeun alkali

Komposisi Kimia,%

| C | Mn | S | Si | Ni | Cu | Fe |

|---|---|---|---|---|---|---|

| .30 max | 2.00 max | .024 max | .50 max | 63,0 mnt | 28.0-34.0 | 2,50 max |

Monel tahan korosi 400

Paduan 400ampir kebal kana retakan korosi setrés ion klorida dina lingkungan anu biasa. Sacara umum, résistansi korosi na saé pisan dina ngirangan lingkungan, tapi kirang dina kaayaan pangoksidasi. Éta henteu kapaké pikeun ngoksidasi asam, sapertos asam nitrat sareng nitrous. Tapi, éta tahan ka kalolobaan alkali, uyah, cai, produk pangan, zat organik sareng kaayaan atmosfir dina suhu normal sareng luhur.

Campuran nikel ieu diserang dina gas anu ngandung walirang di luhur kira-kira 700 ° F jeung walirang lebur narajang alloy dina suhu leuwih ti 500 ° F.

Monel 400 nawiskeun ngeunaan résistansi korosi anu sami sareng nikel tapi kalayan tekanan kerja sareng suhu maksimal anu langkung luhur sareng dina biaya anu langkung handap kusabab kamampuan unggulna pikeun dimesin.

Dina aplikasi naon Monel 400 dianggo?

- Téknik Kelautan

- Alat ngolah kimia sareng hidrokarbon

- Tangki béngsin sareng cai tawar

- Masihan minyak bumi

- De-aerating pamanas

- Pemanas cai feed boiler sareng penukar panas anu sanés

- Klep, pompa, shafts, fittings, sarta fasteners

- Exchangers panas industri

- Pangleyur klorinasi

- munara distilasi minyak atah

Fabrikasi sareng Monel 400

Alloy 400 tiasa gampang dilas ku busur gas-tungsten, busur logam gas atanapi prosés busur logam terlindung nganggo logam pangisi anu pas. Teu perlu pikeun perlakuan panas pos weld, kumaha oge, beberesih teleb sanggeus las kritis pikeun lalawanan korosi optimum, disebutkeun aya résiko kontaminasi na embrittlement.

Fabrikasi rengse bisa dihasilkeun kana rupa-rupa sipat mékanis lamun kontrol ditangtoskeun tina jumlah kerja panas atawa tiis sarta seleksi perlakuan termal luyu geus rengse.

Sapertos kalolobaan alloy nikel anu sanés, Monel 400 biasana tangguh pikeun mesin sareng tiasa dianggo. Nanging, hasil anu saé tiasa didapet upami anjeun milih pilihan anu leres pikeun perkakas sareng mesin.

Kelas Bahan

| Bahan | Standar ASTM A240 | 201, 304 304L 304H 309S 309H 310S 310H 316 316H 316L 316Ti 317 317L 321 321H 347 347H 409 410 410L 410 |

| Standar ASTM A480 | 302, s30215, s30452, s30615, 308, 309, 309Cb, 310, 310Cb, S32615, S33228, S38100, 304H, 309H, 310H, 310H, 310H, 310H, 310H, 310H 321H,347H, 348H, S31060, N08811, N08020, N08367, N08810, N08904, N08926, S31277, S20161, S30600, S30601, S30254, S3102 S32654, S32053, S31727, S33228, S34565, S35315, S31200, S31803, S32001, S32550, S31260, S32003, S32101, S33204 S32520, S32750, S32760, S32900, S32906, S32950, S32974 | |

| JIS 4304-2005 Standar | SUS301L, SUS301J1, SUS302, SUS304, SUS304L, SUS316/316L, SUS309S, SUS310S, 3SUS21L, SUS347, SUS410L, SUS430, SUS630 | |

| JIS G4305 Standar | SUS301, SUS301L, SUS301J1, SUS302B, SUS304, SUS304Cu, SUS304L, SUS304N1, SUS304N2, SUS304LN, SUS304J1, SUSJ2, SUS305, SUS3010S, SUS SUS315J1, SUS315J2, SUS316, SUS316L, SUS316N, SUS316LN, SUS316Ti, SUS316J1, SUS316J1L, SUS317, SUS317L, SUS317LN, SUS317J1, SUS317J1, SUS317J1, SUS317J1, SUSL836J2 SUS321, SUS347, SUSXM7, SUSXM15J1, SUS329J1, SUS329J3L, SUS329J4L, SUS405, SUS410L, SUS429, SUS430, SUS430LX, SUS430J1L, SUS4364 SUS436J1L, SUS444, SUS445J1, SUS445J2, SUS447J1, SUSXM27, SUS403, SUS410, SUS410S, SUS420J1, SUS420J2, SUS440A |

Spésifikasi produk

| Bérés | Kandelna | Ciri | Aplikasi |

| No. 1 | 3.0mm ~ 50.0mm | Réngsé ku panas-rolling, annealing na pickling, dicirikeun ku permukaan pickled bodas | Parabot industri kimia, tank industri |

| No. 2B | 0.3mm ~ 6.0mm | Réngsé ku perlakuan panas, pickling sanggeus rolling tiis, dituturkeun ku garis pass kulit janten permukaan leuwih caang jeung lemes | Aplikasi Umum Alat Médis, Tableware |

| No BA (Bright Annealed) | 0.5mm ~ 2.0mm | perlakuan panas caang sanggeus rolling tiis | Parabot dapur, parabot dapur, tujuan arsitéktur |

| No. 4 | 0.4mm ~ 3.0mm | Polishing kalawan No.. 150 mun No.180 bolong abrasives. The finish pang populerna | fasilitas ngolah susu & dahareun, alat-alat rumah sakit, bak mandi |

| No. 8 | 0.5mm ~ 2.0mm | Permukaan reflektif sapertos eunteung ku ngagosok nganggo abrasive anu langkung saé langkung ti 800 bolong | Reflektor, Eunteung, Interior-Exterior hiasan pikeun wangunan |

| HL (Garis Rambut) | 0.4mm ~ 3.0mm | Réngsé ku polishing linier kontinyu | Tujuan arsitéktur, escalators, kandaraan ware dapur |

Komposisi kimiawi

| Kelas | C | Si | Mn | P | S | Cr | Ni | Mo | Ti | N | Cu | Nb |

| 201 | ≤0.15 | ≤1.0 | 5.50-7.50 | ≤0.05 | ≤0.03 | 16.00-18.00 | 3.50-5.50 | - | - | 0.05-0.25 | - | - |

| 202 | ≤0.15 | ≤1.0 | 7.50-10.00 | ≤0.05 | ≤0.03 | 17.00-19.00 | 4.00-6.00 | - | - | 0.05-0.25 | - | - |

| 301 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0,045 | ≤0.03 | 16.00-18.00 | 6.00-8.00 | - | - | ≤0.1 | - | - |

| 302 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 17.00-19.00 | 8.00-10.00 | - | - | ≤0.1 | - | - |

| 303 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.2 | ≥0.15 | 17.00-19.00 | 8.00-10.00 | ≤0.6 | - | ≤0.1 | - | - |

| 304 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 17.00-19.00 | 8.00-10.00 | - | - | - | - | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 18.00-20.00 | 8.00-10.00 | - | - | - | - | - |

| 304H | 0.04-0.1 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 18.00-20.00 | 8.00-10.00 | - | - | - | - | - |

| 304N | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 18.00-20.00 | 8.00-10.00 | - | - | 0.10-0.16 | - | - |

| 304J1 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 18.00-20.00 | 6.00-9.00 | - | - | - | 1.00-3.00 | - |

| 305 | ≤0.12 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 17.00-19.00 | 10.50-13.00 | - | - | - | - | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 22.00-24.00 | 12.00-15.00 | - | - | - | - | - |

| 310S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 24.00-26.00 | 19.00-22.00 | - | - | - | - | - |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | - | - | - | - |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | 12.00-15.00 | 2.00-3.00 | - | - | - | - |

| 316H | ≤0.1 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | - | - | - | - |

| 316N | ≤0.03 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | - | 0.10-0.16 | - | - |

| 316Ti | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 16.00-19.00 | 11.00-14.00 | 2.00-3.00 | ≥5C | - | - | - |

| 317L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | 3.00-4.00 | - | - | - | - |

| 321 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 17.00-19.00 | 9.00-12.00 | - | 5C-0.7 | - | - | - |

| 347 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 17.00-19.00 | 9.00-12.00 | - | - | - | - | 10C-1.10 |

| 347H | ≤0.1 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 17.00-19.00 | 9.00-12.00 | - | - | - | - | 8C-1.10 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 21.00-24.00 | 4.50-6.50 | 2.50-3.50 | - | 0.08-0.20 | - | - |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0,035 | ≤0.02 | 24.00-26.00 | 6.00-8.00 | 3.00-5.00 | - | 0.24-0.32 | - | - |

| 904L | ≤0.02 | ≤1.0 | ≤2.0 | ≤0,045 | ≤0.03 | 19.00-23.00 | 23.00-28.00 | 4.00-5.00 | - | - | 1.00-2.00 | - |

| C276 | ≤0.02 | ≤0.05 | ≤1.0 | - | - | 14.00-16.50 | Lain | - | - | - | - | - |

| Monel400 | ≤0.3 | ≤0.5 | ≤2.0 | - | ≤0,024 | - | ≥63 | - | - | - | 28-34 | - |

| 409L | ≤0.03 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 17.00-19.00 | - | - | - | - | - | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 11.50-13.50 | - | - | - | - | - | - |

| 410L | ≤0.03 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 11.50-13.50 | - | - | - | - | - | - |

| 420J1 | 0.16-0.25 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 12.00-14.00 | - | - | - | - | - | - |

| 420J2 | 0.26-0.40 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 12.00-14.00 | - | - | - | - | - | - |

| 430 | ≤0.12 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | - | - | - | - | - | - |

| 436L | ≤0,025 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 16.00-19.00 | - | - | - | - | - | - |

| 439 | ≤0.03 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | - | - | - | - | - | - |

| 440A | 0.60-0.75 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | - | ≤0,75 | - | - | - | - |

| 440B | 0.75-0.95 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | - | ≤0,75 | - | - | - | - |

| 440C | 0.95-1.2 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | - | ≤0,75 | - | - | - | - |

| 441 | ≤0.03 | 0.2-0.8 | ≤0.7 | ≤0.03 | ≤0,015 | 17.50-18.50 | - | ≤0.5 | 0.1-0.5 | ≤0,025 | - | 0.3+3C-0.9 |

UrangBungkus produk stainless steel sareng kertas anti karat sareng cincin baja pikeun nyegah karusakan.

Labél idéntifikasi ditandaan nurutkeun spésifikasi standar atanapi paréntah palanggan.

packing husus geus sadia sakumaha per sarat customer urang.

Pakét Coil Stainless Steel

Lambaran Stainless Steel / Paket Lempeng Stainless Steel

Pakét Jalur Stainless Steel

Paket Pangiriman

Perusahaan kami dumasar di Wuxi, ngumpul kota stainless steel industri di Cina.

Kami khusus dina gulungan stainless, sepré sareng piring, pipa baja stainless sareng fitting, tabung stainless steel, sareng ogé produk aluminium sareng produk tambaga.

produk urang geus kacida muji ku klien kami ti Éropa, Amerika, Wétan Tengah, Afrika jeung Asia Tenggara. Urang bakal nawiskeun produk kalapa sarta layanan komprehensif ka konsumén.

Stainless Steel Kelas: 201, 202, 202cu, 204, 204cu, 303, 304, 304L, 308, 308L, 309, 309s, 310, 310s, 316, 316L, 47, 41, 321, 47 430, 430F, 440, 440c,

Kelas Paduan: Monel, Inconel, Hastolley, Duplex, Super Duplex, Titanium, Tantalum, High Speed Steel, Hampang Steel, Aluminium, Alloy Steel, Karbon Steel, Special Nikel Alloys

Dina bentuk: Bar Bulat, Bar Square, Bar Heksagonal, Bar Datar, Sudut, Saluran, Profil, Kawat, Batang Kawat, Lembar, Piring, Pipa Seamless, Pipa ERW, Flanges, Fittings, jsb.

Q1: Naon stainless?

A: Stainless hartina euweuh tanda dina beungeut baja, atawa jenis baja nu teu ruksak ku hawa atawa cai jeung nu teu robah warna ka warna, spotless, tahan ka staining, rusting, pangaruh corrosive bahan kimia.

Q2: Dupi stainless hartosna euweuh rusting?

A: No, stainless hartina teu gampang meunang patri atawa Rusty, éta mibanda kamampuhan speical mun reisist staining, rusting sarta korosi.

Q3: Dupi anjeun nyadiakeun cadar stainless steel?

A: Sumuhun, urang nyadiakeun tipena béda cadar stainless steel, kalayan ketebalan Bulan ti 0.3-3.0mm. sarta dina finish béda.

Q4: Naha anjeun nampi cut kana jasa panjang?

A: Tangtosna, kapuasan customer mangrupikeun prioritas utama urang.

Q5: Upami abdi gaduh pesenan alit, naha anjeun nampi pesenan alit?

A: Henteu masalah, perhatian anjeun perhatian urang, jumlah leutik nu katampa.

Q6: Kumaha anjeun tiasa ngajamin kualitas produk anjeun?

A: Kahiji, ti mimiti pisan, urang geus geus dilaksanakeun sumanget kana pikiran maranéhanana, nyaéta kualitas hirup, pagawe profésional urang jeung staffs bakal nuturkeun nepi unggal hambalan dugi barang dipak ogé sarta shipped kaluar.

Q7: Dupi anjeun pak produk?

A: Jalma profésional ngalakukeun packing profésional, urang boga tipena béda packing pilihan pikeun konsumén, ékonomi hiji atawa hadé.

Q8: Naon nu peryogi kauninga ti customer saméméh cutatan akurat?

A: Pikeun hiji cutatan akurat, urang kudu nyaho kelas, ketebalan, ukuran, permukaan finish, warna jeung kuantitas pesenan anjeun, sarta ogé tujuan barang. Inpo produk ngaropéa bakal diperlukeun deui, kawas gambar, perenah jeung rencana. Teras kami bakal nawiskeun petik kalapa sareng inpormasi di luhur.

Q9: Jenis istilah pembayaran anjeun accpet?

A: Kami nampi T / T, West union, L / C.

Q10: Upami ieu pesenan leutik, anjeun bakal ngirim barang ka agén kami?

A: Sumuhun, urang dilahirkeun pikeun ngajawab masalah konsumén urang, urang bakal meunang barang aman ka gudang agén anjeun sarta ngirim anjeun gambar.

Q11: Naha anjeun ngan ukur ngadamel lambaran datar? Abdi hoyong ngadamel fabrikasi pikeun proyék énggal abdi.

A: No, urang utamana ngahasilkeun perlakuan permukaan lambar datar stainless steel, dina waktos anu sareng, urang rancang logam ngaropéa produk rengse sakumaha per gambar customer sarta rencana, teknisi urang bakal ngurus sésana.

Q12: Sabaraha coutries anjeun geus diékspor?

A: diékspor ka leuwih ti 50 nagara utamana ti Amérika, Rusia, Inggris, Kuwait, Mesir, Iran,

Turki, Yordania, jsb.

Q13: Kumaha carana abdi tiasa sababaraha sampel?

A: Sampel leutik di toko sareng tiasa nyayogikeun conto gratis. Catalgue sadia, paling

pola kami geus siap sampel di stock. sampel ngaropéa bakal nyandak ngeunaan 5-7days.

Q14: Naon pangiriman?

A: waktos pangiriman sampel urutan urang téh 5-7 poé. Pesenan wadahna sakitar 15-20 dinten.

Q15: Naon aplikasi ngeunaan Produk anjeun?

A: 1.elevator panto / kabin atawa na escalator urang sisi-témbok.

2. Wall cladding di jero atawa di luar kamar pasamoan / réstoran.

3.Fasad nalika cladding leuwih hal, kawas kolom di lobi.

4. Plafon di supermarket. 5.Dekoratif draws di sababaraha tempat hiburan.

Q16: Sabaraha lami Anjeun tiasa ngajamin pikeun Produk ieu / rengse?

A: jaminan Warna pikeun leuwih ti 10 taun. Sertipikat kualitas bahan asli tiasa

disadiakeun.