Reasonable price for Stainless Steel Channel Bar - Cr20Ni80 0.3mm 8020 Nichrome 80 wire NiCr alloy for heating – Cepheus

Short Description:

Reasonable price for Stainless Steel Channel Bar - Cr20Ni80 0.3mm 8020 Nichrome 80 wire NiCr alloy for heating – Cepheus Detail:

Alloy 20 / UNS N08020 / W.Nr. 2.4660

Description

Alloy 20 is a nickel-iron-chromium based, austenitic alloy with excellent corrosion resistance in chemical environments containing sulfuric acid and many other aggressive media. This alloy is stabilized with niobium to resist intergranular corrosion. Alloy 20 may provide potential cost savings when carefully compared to higher nickel-based alloys, while out performing standard stainless steels.

Industries and Applications

Alloy 20 is used in a variety of industries, including chemical processing, petrochemical and refining, marine, pharmaceutical and food processing. End use applications include storage tanks, mixing tanks, agitators, pump and valve parts, food processing equipment, fasteners and fittings. Applications are limited to a maximum temperature of 1000°F per ASME. It is also important to determine if the necessary corrosion resistance can be achieved within the given environment.

Resistance to Corrosion

Alloy 20 has very good resistance to sulfuric acid. This alloy also shows suitable resistance in phosphoric acid, nitric acid and aqueous salt solutions. Alloy 20 is an excellent option when chloride stress corrosion cracking is an issue, as it resists pitting and crevice corrosion. Caution should be taken in chloride ion containing environments because the corrosion rate can increase significantly.

Fabrication and Heat Treatment

Alloy 20 can be formed by either hot-working or cold-work using traditional methods. Hot forged material should be heated between 2100°F and 2250°F with careful temperature control insuring that the material not fall below 1800°F prior to forging. After hot working, anneal the material by heating to 1725°F and 1850°F for a minimum of 30 minutes per inch of thickness followed by water quench.

When stress relieving is desired, heat to a temperature below 1000°F followed by water quench after the desired time at temperature has been established. Annealing Alloy 20 should be between 1725°F and 1850°F for 30 minutes at temperature per inch of thickness. A lower hardness can be obtained by heating to 2100°F but his may have a negative effect on the stabilization of the alloy.

Welding Alloy 20 is commonly performed via, TIG, MIG as well as submerged arc welding (SAW) using either the matching filler metal, ER320LR for TIG and MIG and E320LR for SAW. When welding to dissimilar alloys such as 316 or higher alloys such as C276 and Alloy 22, AWS ERNiCrMo-3 can be used for TIG and MIG while using ENiCrMo-3 for SAW.

Common Trade Names

INCOLOY® alloy 20, Carpenter® 20 alloy, 20CB-3®

INCOLOY® is a registered trademark of the Special Metals Corporation group of companies.

Carpenter® and 20CB-3® are registered trademarks of Carpenter.

Chemical Composition (%)

| (Fe) Iron | Remainder |

| (Ni) Nickel | 32.00 to 38.00 |

| (Cr) Chromium | 19.00 to 21.00 |

| (Cu) Copper | 3.00 to 4.00 |

| (Mo) Molybdenum | 2.00 to 3.00 |

| (Mn) Manganese | 2.00 max |

| (Nb+Ta) Niobium* + Tantalum | (8 x C) to 1.00 |

| (Si) Silicon | 1.00 max |

| (C) Carbon | 0.07 max |

| (P) Phosphorus | 0.045 max |

| (S) Sulfur | 0.035 max |

*Niobium (Nb) formerly classified as Columbium (Cb).

Applicable Specifications*

| Form | ASTM | ASME |

| Bar | B473 | SB473 |

| Sheet & Plate | B463 | SB463 |

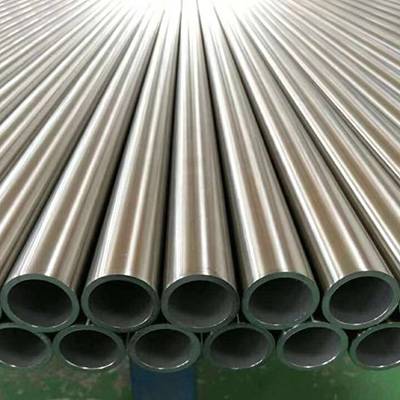

| Seamless Pipe & Tube | B729 | SB729 |

| Welded Pipe | B464, B4741 | SB464, SB474 |

| Welded Tube | B468 | SB468 |

* EN10204-3.1 applies to all product forms.

1Electric fusion welded pipe material only.

Product detail pictures:

Related Product Guide:

Emergency Showers and Eyewash: Stem Shield | Stainless Steel Pipe Fittings

Global Seamless Steel Pipes Market Study for 2018 to 2023 providing information of Top Companies, Trends, Growth Factors and Industry challenges of Top 20 Countries Data | Stainless Steel Pipes

We've got a specialist, effectiveness staff to supply high quality service for our shopper. We always follow the tenet of customer-oriented, details-focused for Reasonable price for Stainless Steel Channel Bar - Cr20Ni80 0.3mm 8020 Nichrome 80 wire NiCr alloy for heating – Cepheus, The product will supply to all over the world, such as: Kenya, Honduras, Malaysia, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly solutions, reuse on the solution. We've Updated our catalog, which introduces our organization. n detail and covers the primary products we provide at present, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

Material Grade

| Material | ASTM A240 Standard | 201, 304 304L 304H 309S 309H 310S 310H 316 316H 316L 316Ti 317 317L 321 321H 347 347H 409 410 410S 430 904L |

| ASTM A480 Standard | 302, s30215, s30452, s30615, 308, 309, 309Cb, 310, 310Cb, S32615,S33228, S38100, 304H, 309H, 310H, 316H, 309HCb, 310HCb, 321H,347H, 348H, S31060, N08811, N08020, N08367, N08810, N08904,N08926, S31277, S20161, S30600, S30601, S31254, S31266,S32050, S32654, S32053, S31727, S33228, S34565, S35315,S31200, S31803, S32001, S32550, S31260, S32003, S32101,S32205, S32304, S32506, S32520, S32750, S32760, S32900, S32906, S32950, S32974 | |

| JIS 4304-2005 Standard | SUS301L,SUS301J1,SUS302,SUS304, SUS304L, SUS316/316L, SUS309S, SUS310S, 3SUS21L, SUS347, SUS410L, SUS430, SUS630 | |

| JIS G4305 Standard | SUS301, SUS301L, SUS301J1, SUS302B, SUS304, SUS304Cu,SUS304L, SUS304N1, SUS304N2, SUS304LN, SUS304J1, SUSJ2,SUS305, SUS309S, SUS310S, SUS312L, SUS315J1, SUS315J2,SUS316, SUS316L, SUS316N, SUS316LN, SUS316Ti, SUS316J1,SUS316J1L,SUS317, SUS317L, SUS317LN, SUS317J1, SUS317J2,SUS836L, SUS890L, SUS321, SUS347, SUSXM7, SUSXM15J1, SUS329J1, SUS329J3L, SUS329J4L, SUS405, SUS410L, SUS429, SUS430, SUS430LX, SUS430J1L, SUS434, SUS436L, SUS436J1L,SUS444, SUS445J1, SUS445J2, SUS447J1, SUSXM27, SUS403,SUS410, SUS410S, SUS420J1, SUS420J2, SUS440A |

Product Specification

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments, Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware, architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasives. The most popular finishes | Milk & Food processing facilities, Hospital Equipment, Bath-tub |

| No. 8 | 0.5mm~2.0mm | A mirror-like reflective surface by polishing with finer abrasives over 800 mesh | Reflector, Mirror, Interior-Exterior decoration forbuilding |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

Chemical Composition

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Ti |

N |

Cu |

Nb |

|

201 |

≤0.15 |

≤1.0 |

5.50-7.50 |

≤0.05 |

≤0.03 |

16.00-18.00 |

3.50-5.50 |

- |

- |

0.05-0.25 |

- |

- |

|

202 |

≤0.15 |

≤1.0 |

7.50-10.00 |

≤0.05 |

≤0.03 |

17.00-19.00 |

4.00-6.00 |

- |

- |

0.05-0.25 |

- |

- |

|

301 |

≤0.15 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

16.00-18.00 |

6.00-8.00 |

- |

- |

≤0.1 |

- |

- |

|

302 |

≤0.15 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

8.00-10.00 |

- |

- |

≤0.1 |

- |

- |

|

303 |

≤0.15 |

≤1.0 |

≤2.0 |

≤0.2 |

≥0.15 |

17.00-19.00 |

8.00-10.00 |

≤0.6 |

- |

≤0.1 |

- |

- |

|

304 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

8.00-10.00 |

- |

- |

- |

- |

- |

|

304L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

18.00-20.00 |

8.00-10.00 |

- |

- |

- |

- |

- |

|

304H |

0.04-0.1 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

18.00-20.00 |

8.00-10.00 |

- |

- |

- |

- |

- |

|

304N |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

18.00-20.00 |

8.00-10.00 |

- |

- |

0.10-0.16 |

- |

- |

|

304J1 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

18.00-20.00 |

6.00-9.00 |

- |

- |

- |

1.00-3.00 |

- |

|

305 |

≤0.12 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

10.50-13.00 |

- |

- |

- |

- |

- |

|

309S |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

22.00-24.00 |

12.00-15.00 |

- |

- |

- |

- |

- |

|

310S |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

24.00-26.00 |

19.00-22.00 |

- |

- |

- |

- |

- |

|

316 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

10.00-14.00 |

2.00-3.00 |

- |

- |

- |

- |

|

316L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

12.00-15.00 |

2.00-3.00 |

- |

- |

- |

- |

|

316H |

≤0.1 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

10.00-14.00 |

2.00-3.00 |

- |

- |

- |

- |

|

316N |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

10.00-14.00 |

2.00-3.00 |

- |

0.10-0.16 |

- |

- |

|

316Ti |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

16.00-19.00 |

11.00-14.00 |

2.00-3.00 |

≥5C |

- |

- |

- |

|

317L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

18.00-20.00 |

11.00-15.00 |

3.00-4.00 |

- |

- |

- |

- |

|

321 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

9.00-12.00 |

- |

5C-0.7 |

- |

- |

- |

|

347 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

9.00-12.00 |

- |

- |

- |

- |

10C-1.10 |

|

347H |

≤0.1 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

9.00-12.00 |

- |

- |

- |

- |

8C-1.10 |

|

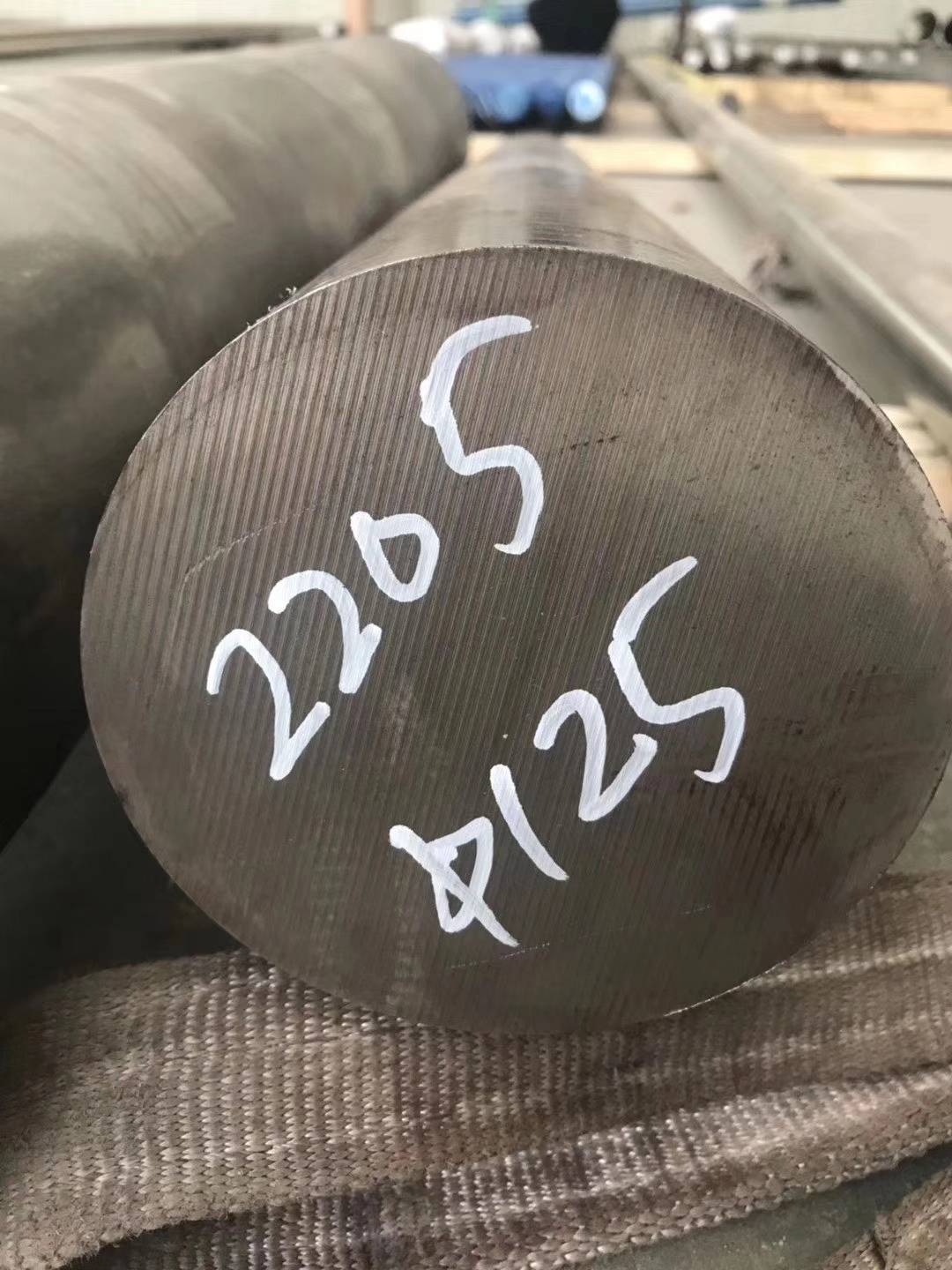

2205 |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

21.00-24.00 |

4.50-6.50 |

2.50-3.50 |

- |

0.08-0.20 |

- |

- |

|

2507 |

≤0.03 |

≤0.8 |

≤1.2 |

≤0.035 |

≤0.02 |

24.00-26.00 |

6.00-8.00 |

3.00-5.00 |

- |

0.24-0.32 |

- |

- |

|

904L |

≤0.02 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

19.00-23.00 |

23.00-28.00 |

4.00-5.00 |

- |

- |

1.00-2.00 |

- |

|

C276 |

≤0.02 |

≤0.05 |

≤1.0 |

- |

- |

14.00-16.50 |

Other |

- |

- |

- |

- |

- |

|

Monel400 |

≤0.3 |

≤0.5 |

≤2.0 |

- |

≤0.024 |

- |

≥63 |

- |

- |

- |

28-34 |

- |

|

409L |

≤0.03 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

- |

- |

- |

- |

- |

- |

|

410 |

≤0.15 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

11.50-13.50 |

- |

- |

- |

- |

- |

- |

|

410L |

≤0.03 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

11.50-13.50 |

- |

- |

- |

- |

- |

- |

|

420J1 |

0.16-0.25 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

12.00-14.00 |

- |

- |

- |

- |

- |

- |

|

420J2 |

0.26-0.40 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

12.00-14.00 |

- |

- |

- |

- |

- |

- |

|

430 |

≤0.12 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

- |

- |

- |

- |

- |

- |

|

436L |

≤0.025 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-19.00 |

- |

- |

- |

- |

- |

- |

|

439 |

≤0.03 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

- |

- |

- |

- |

- |

- |

|

440A |

0.60-0.75 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

- |

≤0.75 |

- |

- |

- |

- |

|

440B |

0.75-0.95 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

- |

≤0.75 |

- |

- |

- |

- |

|

440C |

0.95-1.2 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

- |

≤0.75 |

- |

- |

- |

- |

|

441 |

≤0.03 |

0.2-0.8 |

≤0.7 |

≤0.03 |

≤0.015 |

17.50-18.50 |

- |

≤0.5 |

0.1-0.5 |

≤0.025 |

- |

0.3+3C-0.9 |

We wrap the stainless steel products with anti-rust paper and steel rings to prevent damage.

Identification labels are tagged accordingto standard specification or customer’s instructions.

Special packing is available as per customer’s requirement.

Stainless Steel Coil Package

Stainless Steel Sheet / Stainless Steel Plate Package

Stainless Steel Strip Package

Shipment Package

Our company is based in Wuxi, gathering city of industrial stainless steel in China.

We specialized in stainless coils, sheets and plate, stainless steel pipe and fittings, stainless steel tubes, and also aluminum products and copper products.

Our products have been highly praised by our clients from Europe, America, the Middle East, African and Southeast Asia. We will offer competitive products and comprehensive service to customers.

Stainless Steel Grade: 201, 202, 202cu, 204, 204cu, 303, 304, 304L, 308, 308L, 309, 309s, 310, 310s, 316, 316L, 321, 347, 410, 416, 420, 430, 430F, 440, 440c,

Alloy Grade :Monel, Inconel, Hastolley, Duplex, Super Duplex, Titanium, Tantalum, High Speed Steel, Mild Steel, Aluminium, Alloy Steel, Carbon Steel, Special Nickel Alloys

In form of : Round Bars, Square Bars, Hexagonal Bars, Flat Bars, Angles, Channels, Profiles, Wires, Wire Rods, Sheets, Plates, Seamless Pipes, ERW Pipes, Flanges, Fittings,etc.

Q1: What is stainless?

A: Stainless means no marks on the steel surface, or a kind of steel that is not damaged by air or water and that does not change color, spotless, resistant to staining, rusting, the corrosive effect of chemicals.

Q2: Does stainless mean no rusting?

A: No, stainless means not easy to get stained or rusty, it has speical ability to reisist staining, rusting and corrosion.

Q3: Do you supply stainless steel sheets?

A: Yes, we supply different types of stainless steel sheets, with thickness ranges from 0.3-3.0mm. and in different finishes.

Q4: Do you accept cut to length service?

A: Of course, customer’s satisfaction is our top priority.

Q5: If i have a small order, do you accept small order?

A: Not a problem, your concern is our concern, small quantities are accepted.

Q6: How can you guarantee your product quality?

A: First, from the very start, we have already implemented a spirit to their mind, that is quality is life, our professional workers and staffs will follow up every step till the goods packed well and shipped out.

Q7: Will you pack the products?

A: Professional people do professional packing, we have different types of packing optional to customers, economic one or better one.

Q8: What do you need to know from customer before accurate quotation?

A: For an accurate quotation, we need to know grade, thickness, size, surface finish, color and quantity of your order, and also the destination of the goods. Customized product information will be needed more, like drawing, layout and plan. Then we will offer competitive quotation with the above information.

Q9: What kind of payment term you accpet?

A: We accept T/T, West union, L/C.

Q10: If this is a small order, will you delivery the goods to our agent?

A: Yes, we are born to solve problems of our customers, we will get the goods safely to your agent’s warehouse and send you the pictures.

Q11: Do you just make flat sheet? I want to make a fabrication for my new project.

A: No, we mainly produce stainless steel flat sheet surface treatment, at the same time, we manufacture customized metal finished product as per customer’s drawing and plan, our technician will take care of the rest.

Q12: How many coutries you already exported ?

A: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait, Egypt, Iran,

Turkey, Jordan, etc.

Q13: How can I get some samples?

A: Small samples in store and can provide the samples for free. Catalgue is available, most

patterns we have ready samples in stock. Customized samples will take about 5-7days.

Q14: What is the delivery ?

A: Sample order’s delivery time is 5- 7 days. Container orders are about 15-20 days.

Q15: What is the application about your Products?

A: 1.elevator door/cabin or and escalator’s side-wall.

2.Wall cladding inside or outside meeting room/ restaurant.

3.Facade when cladding over something, like columns in the lobby.

4.Ceiling in the supermarket. 5.Decorative draws in some entertainment places.

Q16: How long Can You Guarantee for This Product/Finish?

A: Color guarantee for more than 10 years. Original materials quality certificate can

be provided.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!