Original Factory Stainless Steel Black Surface Round Bar - This low lead C17300 with Pb<0.1%, but its cutting performance is as same as C17300. – Cepheus

Short Description:

Original Factory Stainless Steel Black Surface Round Bar - This low lead C17300 with Pb<0.1%, but its cutting performance is as same as C17300. – Cepheus Detail:

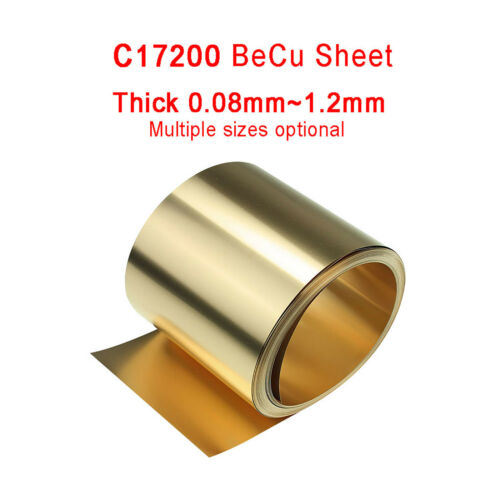

C17200 Details:

C17200 Beryllium Copper

Cube2–C17200 (CDA 172) Beryllium Copper is the most commonly utilized Copper Beryllium alloy and is notable for its highest strength and hardness compared to commercial copper alloys. C17200 alloy contains appr. 2% of beryllium and achieves its ultimate tensile strength can exceed 200 ksi, while the hardness approaches Rockwell C45. Meanwhile, the electrical conductivity is a minimum of 22% IACS in the fully aged condition.C17200 also exhibits exceptional resistance to stress relaxation at elevated temperatures.

Typical Application for C17200 Beryllium Copper Alloys:

Electrical Industry: Electrical Switch and Relay Blades, Fuse Clips, Switch Parts, Relay parts, Connectors, Spring Connectors, Contact Bridges, Belleville Washers, Navigational Instruments, Clips

Fasteners: Washers, Fasteners, Lock Washers, Retaining Rings, Roll Pins, Screws, Bolts

Industrial: Pumps, Springs, Electrochemical, Shafts, Non Sparking Safety Tools, Flexible Metal Hose, Housings for Instruments, Bearings, Bushings, Valve Seats, Valve Stems, Diaphragms, Springs, Welding Equipment, Rolling Mill Parts, Spline Shafts, Pump Parts, Valves, Bourdon Tubes, Wear Plates on Heavy Equipment, Bellows

Available Sizes:

Custom Diameter & Sizes, Random Mill lengths

Available Products (forms):

Round bars, Round strips, Round wires, Round tube,

Flat bars, Square bars, Rectangular bars, Hexagon bars, Plates, Sheets, Coils

Custom shapes are available upon request.

Be: 1.85-2.10%

Co+Ni: 0.20% Min.

Co+Ni+Fe: 0.60% Max.

Cu: Balance

Note: Copper plus additions equal 99.5% minimum.

Density (g/cm3): 8.36

Density before age hardening (g/cm3): 8.25

Elastic Modulus (kg/mm2 (103)): 13.40

Thermal Expansion Coefficient (20 °C to 200 °C m/m/°C): 17 x 10-6

Thermal Conductivity (cal/(cm-s-°C)): 0.25

Melting Range (°C): 870-980

Note:

1). the units are based upon Metric.

2). the typical physical properties apply to age hardened products.

Rods/Bars/Tubes: ASTM B196,251,463; SAE J461,463; AMS 4533,4534,4535; AMS4650,4651;

RWMA Class 4

Strips: ASTM B194, AMS4530,4532; SAE J461,463

Sheets: ASTM B194

Wires: ASTM B197, AMS4725, SAE J461,463

Plates: ASTM B194, SAE J461,463; AMS4530,4533,4534,AMS4650,4651; RWMA Class 4.

European Standards: CuBe2, DIN 2.1247, CW101C to EN

Note:

ASTM: American Society for Testing and Materials

SAE: Society of Automotive Engineers

AMS: Aerospace Materials Specification (Published by SAE)

RWMA: Resistance Welder Manufacturers’ Association

Note: Unless otherwise specified, material will be produced to ASTM.

The Mechanical Properties will be available on request from customers.

Most Commonly Temper Used:

Rods/Bars/Tubes: A(TB00),H(TD04),AT(TF00),HT(TH04)

Strips: A(TB00),1/4 H(TD01),1/2 H(TD02),H(TD04)

Sheets: A(TB00),1/4 H(TD01),1/2 H(TD02),H(TD04),AT(TF00)

Wires: A(TB00),1/4 H(TD01),1/2 H(TD02),3/4H(TD03),H(TD04)

Plates: A(TB00),H(TD04),AT(TF00),HT(TH04)

BERYLLIUM COPPER PHYSICAL & CHEMICAL PROPERTIES

| Beryllium Copper Physical Properties 25 C17200 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Yield Strength | 108 cyclesksi | Hardness | |||||||

| Temper | Heat Treatment | Tensile Strength ksi | 0.2% offset ksi | Elongation % | Fatigue Strength | Diamond Pyramid | Rockwell B or C | Rockwell Superficial | Electrical Conductivity % IACS |

| A Dead Soft (TB00) | – | 60-76 | 28-36 | 35-65 | 30-35 | 90-144 | B45-78 | 30T46-67 | 15-19 |

| A Planished (TB00) | – | 60-78 | 30-55 | 35-60 | 30-35 | 90-144 | B45-78 | 30T46-67 | 15-19 |

| 1/4 H (TD01) | – | 75-88 | 60-80 | 20-45 | 31-36 | 121-185 | B68-90 | 30T62-75 | 15-19 |

| 1/2 H(TD02) | – | 85-100 | 75-95 | 12-30 | 32-38 | 176-216 | B88-96 | 30T74-79 | 15-19 |

| H (TD04) | – | 100-120 | 90-115 | 2-18 | 35-39 | 216-287 | B96-102 | 30T79-83 | 15-19 |

| AT (TF00) | 3 hr. at 600 °F | 165-195 | 140-175 | 3-15 | 40-45 | 353-413 | C36-42 | 30N56-62 | 22-28 |

| 1/4 HT (TH01) | 2 hr. at 600 °F | 175-205 | 150-185 | 3-10 | 40-45 | 353-424 | C36-43 | 30N56-63 | 22-28 |

| 1/2 HT (TH02) | 2 hr. at 600 °F | 185-215 | 160-195 | 1-8 | 42-47 | 373-435 | C38-44 | 30N58-63 | 22-28 |

| HT (TH04) | 2 hr. at 600 °F | 190-220 | 165-205 | 1-6 | 45-50 | 373-446 | C38-45 | 30N58-65 | 22-28 |

| Beryllium Copper Physical Properties 190 C17200 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Yield Strength | 108 Cyclesksi | Hardness | |||||||

| Temper | Heat Treatment | Tensile Strength ksi | 0.2% offset ksi | Elongation % | Fatigue Strength | Diamond Pyramid | Rockwell B or C | Rockwell Superficial | Electrical Conductivity % IACS |

| AM (TM00) | Mill Hardened | 100-110 | 70-95 | 16-30 | 40-45 | 210-251 | B95-C23 | 30N37-44 | 17-28 |

| 1/4 HM (TM01) | Mill Hardened | 110-120 | 80-110 | 15-25 | 41-47 | 230-271 | C20-26 | 30N41-47 | 17-28 |

| 1/2 HM (TM02) | Mill Hardened | 120-135 | 95-125 | 12-22 | 42-48 | 250-301 | C23-30 | 30N44-51 | 17-28 |

| HM (TM04) | Mill Hardened | 135-150 | 110-135 | 9-20 | 45-52 | 285-343 | C28-35 | 30N48-55 | 17-28 |

| SHM (TM05) | Mill Hardened | 150-160 | 125-140 | 9-18 | 47-55 | 309-363 | C31-37 | 30N52-56 | 17-28 |

| XHM (TM06) | Mill Hardened | 155-175 | 135-170 | 4-15 | 50-57 | 317-378 | C32-38 | 30N52-58 | 17-28 |

| XHMS (TM08) | Mill Hardened | 175-190 | 150-180 | 3-12 | 50-60 | 325-413 | C33-42 | 30N53-62 | 17-28 |

| Beryllium Copper Physical Properties 290 C17200 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Yield Strength | 108 Cyclesksi | Hardness | |||||||

| Temper | Heat Treatment | Tensile Strength ksi | 0.2% offset ksi | Elongation % | Fatigue Strength | Diamond Pyramid | Rockwell B or C | Rockwell Superficial | Electrical Conductivity % IACS |

| TM00 | Mill Hardened | 100 min | 75-95 | 19-35 | 40-45 | 225-309 | B98-C31 | 30T81-30N52 | 17-26 |

| TM02 | Mill Hardened | 120 min | 95-115 | 14-30 | 42-48 | 255-339 | C25-34 | 30N46-54 | 17-26 |

| TM04 | Mill Hardened | 140 min | 115-135 | 9-25 | 44-50 | 285-369 | C28-38 | 30N48-58 | 17-26 |

| TM06 | Mill Hardened | 155 min | 135-155 | 6-13 | 47-57 | 317-393 | C32-40 | 30N52-60 | 17-26 |

| TM08 | Mill Hardened | 175 min | 155-175 | 3-15 | 50-60 | 345-429 | C35-43 | 30N55-62 | 17-26 |

| Beryllium Copper Physical Properties 174 C17410 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Yield Strength | 108 Cyclesksi | Hardness | |||||||

| Temper | Heat Treatment | Tensile Strength ksi | 0.2% offset ksi | Elongation % | Fatigue Strength | Diamond Pyramid | Rockwell B or C | Rockwell Superficial | Electrical Conductivity % IACS |

| 1/2 HT (TH02) | Mill Hardened | 95-115 | 80-100 | 10-20 | 40-45 | 180-230 | B89-98 | 30T75-81.9 | 50 min |

| HT (TH04) | Mill Hardened | 110-130 | 100-120 | 7-17 | 40-45 | 210-278 | B95-102 | 30T79-30N48 | 45-60 |

| Beryllium Copper Physical Properties 3 C17510 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Yield Strength | 108 Cyclesksi | Hardness | |||||||

| Temper | Heat Treatment | Tensile Strength ksi | 0.2% offset ksi | Elongation % | Fatigue Strength | Diamond Pyramid | Rockwell B or C | Rockwell Superficial | Electrical Conductivity % IACS |

| A (TB00) | - | 35-55 | 20-45 | 20-40 | 20-30 | 65-125 | B20-45 | 30T28-45 | 20-30 |

| H (TD04) | - | 70-85 | 55-80 | 2-10 | 25-35 | 144-176 | B78-88 | 30T69-75 | 20-30 |

| AT (TF00) | Mill Hardened | 100-130 | 80-100 | 10-25 | 38-44 | 195-275 | B92-100 | 30T77-82 | 45-60 |

| HT (TH04) | Mill Hardened | 110-135 | 95-120 | 8-20 | 42-47 | 216-287 | B95-102 | 30T79-83 | 48-60 |

| Beryllium Copper Physical Properties Brush 60 C17460 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Yield Strength | 108 Cyclesksi | Hardness | |||||||

| Temper | Heat Treatment | Tensile Strength ksi | 0.2% offset ksi | Elongation % | Fatigue Strength | Diamond Pyramid | Rockwell B or C | Rockwell Superficial | Electrical Conductivity % IACS |

| 3/4 HT (TH03) | Mill Hardened | 115-135 | 95-115 | 11min | 46-47 | 50min | |||

| HT (TH04) | Mill Hardened | 120-140 | 105-125 | 10min | 42-45 | 50min | |||

| Copper Beryllium Strip Specifications | ||

|---|---|---|

| Materion Brush Performance Alloys | UNS Number | Specification |

| 25 | C1720 | ASTM B194 |

| 190 | C17200 | ASTM B194 |

| 290 | C17200 | ASTM B194 |

| 3 | C17510 | ASTM B534 |

| 174 | C17410 | ASTM B768 |

| Brush 60 | C17460 | ASTM B768 |

Beryllium Copper BeCu P2 | Beryllium Copper C1720P | Beryllium Copper C1720R | Beryllium Copper AMS 4530 | Beryllium Copper AMS 4532 | Beryllium Copper AMS 4533 | Beryllium Copper AMS 4534 | Beryllium Copper AMS 4535 | Beryllium Copper AMS 4650 | Beryllium Copper AMS 4651 | Beryllium Copper AMS 4725 | Beryllium Copper API Spec 7 | Beryllium Copper ASNA 3384 | Beryllium Copper ASNA 3400 | Beryllium Copper ASNA 3417 | Beryllium Copper ASNA 6110 | Beryllium Copper No.172 | Beryllium Copper ASTM B194 | Beryllium Copper ASTM B196 | Beryllium Copper ASTM B197 | Beryllium Copper ASTM B251 | Beryllium Copper ASTM B570 | Beryllium Copper ASTM B643 | Beryllium Copper BMS 7-353 | Beryllium Copper C1720B | Beryllium Copper CNS 10879 | Beryllium Copper CuBe2 | Beryllium Copper 2.1247 | Beryllium Copper CuBe2 DIN 17666 | Beryllium Copper CuBe2 DIN 17670 | Beryllium Copper CuBe2 DIN 17672 | Beryllium Copper CuBe2 DIN 17677 | Beryllium Copper CuBe2 DIN 17800 | Beryllium Copper CuBe2 DIN 17682 | Beryllium Copper CuBe2 DIN 17671 | Beryllium Copper DMS 1904 | Beryllium Copper DMS 2088 | Beryllium Copper CuBe2 | Beryllium Copper CW101C | Beryllium Copper EN 1654 | Beryllium Copper EN 2163 | Beryllium Copper EN 12163 | Beryllium Copper EN 12165 | Beryllium Copper EN 12166 | Beryllium Copper EN 12167 | Beryllium Copper EN 12420 | Beryllium Copper EN 13148 | Beryllium Copper EN 14436 | Beryllium Copper QBe 2 | Beryllium Copper GB3134 | Beryllium Copper GB4431 | Beryllium Copper GB5233 | Kobber-beryllium CuBe2 | | Beryllium Copper CuBe2 ISO R1187 | Beryllium Copper CuBe2 ISO R1983 | Beryllium Copper BeCu P2 | Beryllium Copper C1720B | Beryllium Copper C1720P | Beryllium Copper C1720R | Beryllium Copper BeCu P2 JIS H 3130 | Beryllium Copper BeCu P2 JIS H 3270 | Beryllium Copper BeCu W2 JIS H 3801 | Beryllium Copper BeCu W2 JIS H 3802 | Beryllium Copper BeCu W2 JIS H 3803 | Beryllium Copper KS C1720 | Beryllium Copper MIL-C-21657 | Beryllium Copper Br Be NBN 66.51 | Beryllium Copper Cu Be2 Co Ni NCH 252 of 68 | Beryllium Copper Cu Be2 Co Ni NCH 259 of 70 | Beryllium Copper NFL-14709 | Beryllium Copper NF A51-114 | Beryllium Copper Cu-Be2 Co Ni NEN 6030 | Beryllium Copper Cu-Be2 Co Ni NEN 6033 | Beryllium Copper C1720 | Beryllium Copper QQ-C-530 | Beryllium Copper QQ-C-533 | Beryllium Copper RWMA Class 4 | Beryllium Copper SAE J461 | Beryllium Copper SAE J463 | Beryllium Copper UNS C17200 | Beryllium Copper Werkstoff Nr.2.1247 | Beryllium Copper Brush 190 | Beryllium Copper Mallory | Beryllium Copper Berylco

Product detail pictures:

Related Product Guide:

India to probe subsidised stainless steel imports from China | Stainless Steel Pipes

Stainless steel toilet cubicles customised for Adelaide City tram drivers toilet project | Stainless Steel Elbow For Helium

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for Original Factory Stainless Steel Black Surface Round Bar - This low lead C17300 with Pb<0.1%, but its cutting performance is as same as C17300. – Cepheus, The product will supply to all over the world, such as: Armenia, Norwegian, Slovakia, Why we can do these? Because: A, We are honest and reliable. Our items have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It might be highly appreciated.

Material Grade

| Material | ASTM A240 Standard | 201, 304 304L 304H 309S 309H 310S 310H 316 316H 316L 316Ti 317 317L 321 321H 347 347H 409 410 410S 430 904L |

| ASTM A480 Standard | 302, s30215, s30452, s30615, 308, 309, 309Cb, 310, 310Cb, S32615,S33228, S38100, 304H, 309H, 310H, 316H, 309HCb, 310HCb, 321H,347H, 348H, S31060, N08811, N08020, N08367, N08810, N08904,N08926, S31277, S20161, S30600, S30601, S31254, S31266,S32050, S32654, S32053, S31727, S33228, S34565, S35315,S31200, S31803, S32001, S32550, S31260, S32003, S32101,S32205, S32304, S32506, S32520, S32750, S32760, S32900, S32906, S32950, S32974 | |

| JIS 4304-2005 Standard | SUS301L,SUS301J1,SUS302,SUS304, SUS304L, SUS316/316L, SUS309S, SUS310S, 3SUS21L, SUS347, SUS410L, SUS430, SUS630 | |

| JIS G4305 Standard | SUS301, SUS301L, SUS301J1, SUS302B, SUS304, SUS304Cu,SUS304L, SUS304N1, SUS304N2, SUS304LN, SUS304J1, SUSJ2,SUS305, SUS309S, SUS310S, SUS312L, SUS315J1, SUS315J2,SUS316, SUS316L, SUS316N, SUS316LN, SUS316Ti, SUS316J1,SUS316J1L,SUS317, SUS317L, SUS317LN, SUS317J1, SUS317J2,SUS836L, SUS890L, SUS321, SUS347, SUSXM7, SUSXM15J1, SUS329J1, SUS329J3L, SUS329J4L, SUS405, SUS410L, SUS429, SUS430, SUS430LX, SUS430J1L, SUS434, SUS436L, SUS436J1L,SUS444, SUS445J1, SUS445J2, SUS447J1, SUSXM27, SUS403,SUS410, SUS410S, SUS420J1, SUS420J2, SUS440A |

Product Specification

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments, Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware, architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasives. The most popular finishes | Milk & Food processing facilities, Hospital Equipment, Bath-tub |

| No. 8 | 0.5mm~2.0mm | A mirror-like reflective surface by polishing with finer abrasives over 800 mesh | Reflector, Mirror, Interior-Exterior decoration forbuilding |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

Chemical Composition

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Ti |

N |

Cu |

Nb |

|

201 |

≤0.15 |

≤1.0 |

5.50-7.50 |

≤0.05 |

≤0.03 |

16.00-18.00 |

3.50-5.50 |

- |

- |

0.05-0.25 |

- |

- |

|

202 |

≤0.15 |

≤1.0 |

7.50-10.00 |

≤0.05 |

≤0.03 |

17.00-19.00 |

4.00-6.00 |

- |

- |

0.05-0.25 |

- |

- |

|

301 |

≤0.15 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

16.00-18.00 |

6.00-8.00 |

- |

- |

≤0.1 |

- |

- |

|

302 |

≤0.15 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

8.00-10.00 |

- |

- |

≤0.1 |

- |

- |

|

303 |

≤0.15 |

≤1.0 |

≤2.0 |

≤0.2 |

≥0.15 |

17.00-19.00 |

8.00-10.00 |

≤0.6 |

- |

≤0.1 |

- |

- |

|

304 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

8.00-10.00 |

- |

- |

- |

- |

- |

|

304L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

18.00-20.00 |

8.00-10.00 |

- |

- |

- |

- |

- |

|

304H |

0.04-0.1 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

18.00-20.00 |

8.00-10.00 |

- |

- |

- |

- |

- |

|

304N |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

18.00-20.00 |

8.00-10.00 |

- |

- |

0.10-0.16 |

- |

- |

|

304J1 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

18.00-20.00 |

6.00-9.00 |

- |

- |

- |

1.00-3.00 |

- |

|

305 |

≤0.12 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

10.50-13.00 |

- |

- |

- |

- |

- |

|

309S |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

22.00-24.00 |

12.00-15.00 |

- |

- |

- |

- |

- |

|

310S |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

24.00-26.00 |

19.00-22.00 |

- |

- |

- |

- |

- |

|

316 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

10.00-14.00 |

2.00-3.00 |

- |

- |

- |

- |

|

316L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

12.00-15.00 |

2.00-3.00 |

- |

- |

- |

- |

|

316H |

≤0.1 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

10.00-14.00 |

2.00-3.00 |

- |

- |

- |

- |

|

316N |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

10.00-14.00 |

2.00-3.00 |

- |

0.10-0.16 |

- |

- |

|

316Ti |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

16.00-19.00 |

11.00-14.00 |

2.00-3.00 |

≥5C |

- |

- |

- |

|

317L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

18.00-20.00 |

11.00-15.00 |

3.00-4.00 |

- |

- |

- |

- |

|

321 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

9.00-12.00 |

- |

5C-0.7 |

- |

- |

- |

|

347 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

9.00-12.00 |

- |

- |

- |

- |

10C-1.10 |

|

347H |

≤0.1 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

9.00-12.00 |

- |

- |

- |

- |

8C-1.10 |

|

2205 |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

21.00-24.00 |

4.50-6.50 |

2.50-3.50 |

- |

0.08-0.20 |

- |

- |

|

2507 |

≤0.03 |

≤0.8 |

≤1.2 |

≤0.035 |

≤0.02 |

24.00-26.00 |

6.00-8.00 |

3.00-5.00 |

- |

0.24-0.32 |

- |

- |

|

904L |

≤0.02 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

19.00-23.00 |

23.00-28.00 |

4.00-5.00 |

- |

- |

1.00-2.00 |

- |

|

C276 |

≤0.02 |

≤0.05 |

≤1.0 |

- |

- |

14.00-16.50 |

Other |

- |

- |

- |

- |

- |

|

Monel400 |

≤0.3 |

≤0.5 |

≤2.0 |

- |

≤0.024 |

- |

≥63 |

- |

- |

- |

28-34 |

- |

|

409L |

≤0.03 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

17.00-19.00 |

- |

- |

- |

- |

- |

- |

|

410 |

≤0.15 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

11.50-13.50 |

- |

- |

- |

- |

- |

- |

|

410L |

≤0.03 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

11.50-13.50 |

- |

- |

- |

- |

- |

- |

|

420J1 |

0.16-0.25 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

12.00-14.00 |

- |

- |

- |

- |

- |

- |

|

420J2 |

0.26-0.40 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

12.00-14.00 |

- |

- |

- |

- |

- |

- |

|

430 |

≤0.12 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

- |

- |

- |

- |

- |

- |

|

436L |

≤0.025 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-19.00 |

- |

- |

- |

- |

- |

- |

|

439 |

≤0.03 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

- |

- |

- |

- |

- |

- |

|

440A |

0.60-0.75 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

- |

≤0.75 |

- |

- |

- |

- |

|

440B |

0.75-0.95 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

- |

≤0.75 |

- |

- |

- |

- |

|

440C |

0.95-1.2 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

16.00-18.00 |

- |

≤0.75 |

- |

- |

- |

- |

|

441 |

≤0.03 |

0.2-0.8 |

≤0.7 |

≤0.03 |

≤0.015 |

17.50-18.50 |

- |

≤0.5 |

0.1-0.5 |

≤0.025 |

- |

0.3+3C-0.9 |

We wrap the stainless steel products with anti-rust paper and steel rings to prevent damage.

Identification labels are tagged accordingto standard specification or customer’s instructions.

Special packing is available as per customer’s requirement.

Stainless Steel Coil Package

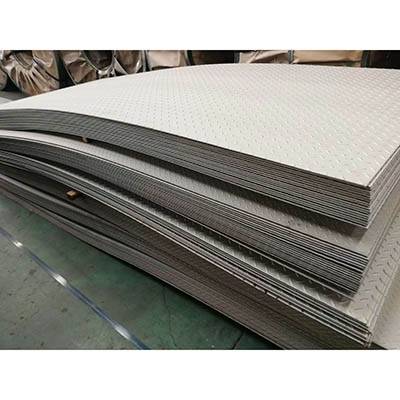

Stainless Steel Sheet / Stainless Steel Plate Package

Stainless Steel Strip Package

Shipment Package

Our company is based in Wuxi, gathering city of industrial stainless steel in China.

We specialized in stainless coils, sheets and plate, stainless steel pipe and fittings, stainless steel tubes, and also aluminum products and copper products.

Our products have been highly praised by our clients from Europe, America, the Middle East, African and Southeast Asia. We will offer competitive products and comprehensive service to customers.

Stainless Steel Grade: 201, 202, 202cu, 204, 204cu, 303, 304, 304L, 308, 308L, 309, 309s, 310, 310s, 316, 316L, 321, 347, 410, 416, 420, 430, 430F, 440, 440c,

Alloy Grade :Monel, Inconel, Hastolley, Duplex, Super Duplex, Titanium, Tantalum, High Speed Steel, Mild Steel, Aluminium, Alloy Steel, Carbon Steel, Special Nickel Alloys

In form of : Round Bars, Square Bars, Hexagonal Bars, Flat Bars, Angles, Channels, Profiles, Wires, Wire Rods, Sheets, Plates, Seamless Pipes, ERW Pipes, Flanges, Fittings,etc.

Q1: What is stainless?

A: Stainless means no marks on the steel surface, or a kind of steel that is not damaged by air or water and that does not change color, spotless, resistant to staining, rusting, the corrosive effect of chemicals.

Q2: Does stainless mean no rusting?

A: No, stainless means not easy to get stained or rusty, it has speical ability to reisist staining, rusting and corrosion.

Q3: Do you supply stainless steel sheets?

A: Yes, we supply different types of stainless steel sheets, with thickness ranges from 0.3-3.0mm. and in different finishes.

Q4: Do you accept cut to length service?

A: Of course, customer’s satisfaction is our top priority.

Q5: If i have a small order, do you accept small order?

A: Not a problem, your concern is our concern, small quantities are accepted.

Q6: How can you guarantee your product quality?

A: First, from the very start, we have already implemented a spirit to their mind, that is quality is life, our professional workers and staffs will follow up every step till the goods packed well and shipped out.

Q7: Will you pack the products?

A: Professional people do professional packing, we have different types of packing optional to customers, economic one or better one.

Q8: What do you need to know from customer before accurate quotation?

A: For an accurate quotation, we need to know grade, thickness, size, surface finish, color and quantity of your order, and also the destination of the goods. Customized product information will be needed more, like drawing, layout and plan. Then we will offer competitive quotation with the above information.

Q9: What kind of payment term you accpet?

A: We accept T/T, West union, L/C.

Q10: If this is a small order, will you delivery the goods to our agent?

A: Yes, we are born to solve problems of our customers, we will get the goods safely to your agent’s warehouse and send you the pictures.

Q11: Do you just make flat sheet? I want to make a fabrication for my new project.

A: No, we mainly produce stainless steel flat sheet surface treatment, at the same time, we manufacture customized metal finished product as per customer’s drawing and plan, our technician will take care of the rest.

Q12: How many coutries you already exported ?

A: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait, Egypt, Iran,

Turkey, Jordan, etc.

Q13: How can I get some samples?

A: Small samples in store and can provide the samples for free. Catalgue is available, most

patterns we have ready samples in stock. Customized samples will take about 5-7days.

Q14: What is the delivery ?

A: Sample order’s delivery time is 5- 7 days. Container orders are about 15-20 days.

Q15: What is the application about your Products?

A: 1.elevator door/cabin or and escalator’s side-wall.

2.Wall cladding inside or outside meeting room/ restaurant.

3.Facade when cladding over something, like columns in the lobby.

4.Ceiling in the supermarket. 5.Decorative draws in some entertainment places.

Q16: How long Can You Guarantee for This Product/Finish?

A: Color guarantee for more than 10 years. Original materials quality certificate can

be provided.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!