Paduan Inconel 625

Katrangan singkat:

Ingot utawa casting alloy nikel utamané diprodhuksi dening casting vakum. Ingots pisanan mbalek, extruded utawa palsu, banjur mbalek utawa digawe dowo sawise perawatan panas penengah, lan pungkasanipun diproses menyang prodhuk sing dikarepake. Sawetara superalloys basis nikel digunakake salah siji langsung karo casting utawa kanthi bagean sing digawe nggunakake metode metalurgi bubuk.

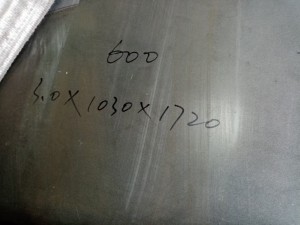

| Lembar Paduan Nikel | |

| Jembar | Hot sade duplex steel 2205 1. 4462 F60stainless steel |

| dawa | 2000mm, 2438mm, 3000mm, 6000mm, utawa minangka request customer kang |

| Pipa Paduan Nikel | |

| kekandelan | 0.5mm-30mm minangka panyuwunan |

| Ukuran | 8mm-530mm minangka panyuwunan sampeyan |

| dawa | 1 meter nganti 6 meter utawa minangka kabutuhan pelanggan |

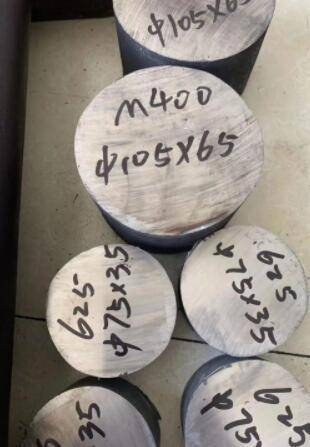

| Nikel Alloy Bar | |

| Dhiameter | 2mm kanggo 400 mm utawa 1/8 "nganti 15" utawa minangka requirement customer |

| dawa | 1 meter nganti 6 meter utawa minangka kabutuhan pelanggan |

| Klasifikasi materi | |

| Monel Alloy Kab | MONEL K-500, Monel400/2.4360, Monel 401. |

| KhususStainlessSteel | 904L/UNS N08904/DIN1.4539, 254SMO/UNS S31254,253MA, 316Ti, 347H. |

| DuplexStainlessSteel | 1. 4462/2205/F60, 1.4028, 1.4016, 1.4006, S32101, S42000, SUS434, 1.4507, SUS416, SUS410, s31500, S32803, S32803/S5 . |

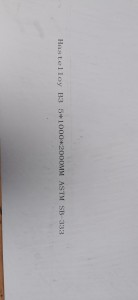

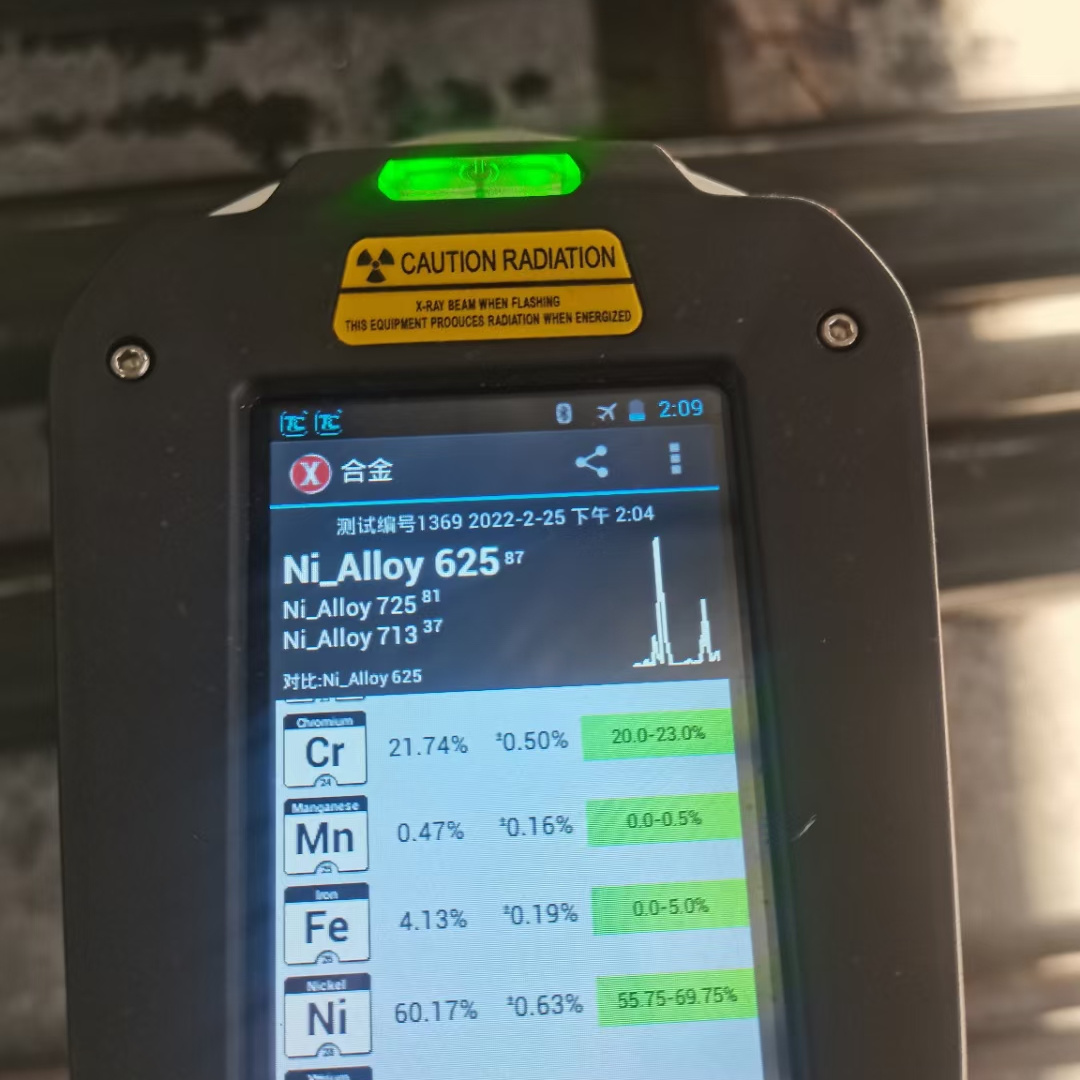

| InconelAlloy | Inconel840 (S33400), Inconel 686 (2.4606-N06686), Inconel725 (NO7725), Inconel713C(2.4671), Inconel625 (2.4856), Inconel602ca (N06625), Inconel (N060 el 690 (2.4642), Inconel617 (N06617), InconelX-750 (750), Inconel804, Inconel718 (2.4668). |

| IncoloyAlloy | Incoloy 800HT, Incoloy 890/1. 6569, Incoloy 810, Incoloy801, Incoloy 840/UNS S33400, Incoloy 20/UNS N08020, Incoloy 926/UNS N08926/1.4529, Incoloy 901/UNS N09901/2.308 488, Incoloy945/ (UNS N09945), incoloy A-286 /(UNSS66286/1.4980) , Incoloy 825/2.4858, Incoloy 925/UNS N09925, Incoloy 800H/80AT0HT/800H/80AT. |

| HighTemperatureAlloy | GH3308, GH3304, GH4090, GH738, GH3030, GH159 (GH6159) , GH3039, GH3044, GH3536, GH5188, GH1131, GH4141, GH80 2132, GH3625, GH3128, GH4145, GH4169, GH605 (GH5605 ), GH93 (GH4093), GH159 (GH6159), Incoloy A-286, Inconel718, Incoloy825/2. 4858. |

| HastelloyAlloy | Paduan HastelloyB-2/Paduan Hastelloy B-2, Paduan HastelloyB3/Paduan Hastelloy B3, Paduan Hastelloy C-2000/Paduan HastelloyC-2000, Paduan Hastelloy C-4/Paduan HastelloyC-4/2.4610, Paduan Hastelloy C-22/Hastelloy AlloyC-276 / Hastelloy C-276 Alloy. |

Kelas Bahan

| Bahan | Standar ASTM A240 | 201, 304 304L 304H 309S 309H 310S 310H 316 316H 316L 316Ti 317 317L 321 321H 347 347H 409 410 410 410 9S |

| Standar ASTM A480 | 302. 347H, 348H, S31060, N08811, N08020, N08367, N08810, N08904, N08926, S31277, S20161, S30600, S30601, S31254, S31266, S32050, S32654, S32053, S31727, S334525, S 03, S32001, S32550, S31260, S32003, S32101, S32205, S32304, S32506, S32520, S32750, S32760, S32900, S32906, S32950, S32974 | |

| JIS 4304-2005 Standar | SUS301L, SUS301J1, SUS302, SUS304, SUS304L, SUS316/316L, SUS309S, SUS310S, 3SUS21L, SUS347, SUS410L, SUS430, SUS630 | |

| JIS G4305 Standar | SUS301, SUS301L, SUS301J1, SUS302B, SUS304, SUS304Cu, SUS304L, SUS304N1, SUS304N2, SUS304LN, SUS304J1, SUSJ2, SUS305, SUS301S, SUS309S, SUS309S, 1SUS J2, SUS316, SUS316L, SUS316N, SUS316LN, SUS316Ti, SUS316J1, SUS316J1L, SUS317, SUS317L, SUS317LN, SUS317J1, SUS317J2, SUS836L, SUS890L, SUS321, SUS347, SUSXM7, SUSXM15J1, SUS329J1, SUS329J3L, SUS329J3L, SUS329J4L, SUS329J4 0, SUS430LX, SUS430J1L, SUS434, SUS436L, SUS436J1L, SUS444, SUS445J1, SUS445J2, SUS447J1, SUSXM27, SUS403, SUS410, SUS410S, SUS420J1, SUS420J2, SUS440A |

Spesifikasi Produk

| Rampung | kekandelan | Karakteristik | Aplikasi |

| No. 1 | 3.0mm ~ 50.0mm | Rampung kanthi panas-rolling, annealing lan pickling, ditondoi dening permukaan pickled putih | Peralatan industri kimia, tank industri |

| No. 2B | 0.3mm ~ 6.0mm | Rampung dening perawatan panas, pickling sawise Rolling kadhemen, ngiring dening kulit pass line dadi lumahing luwih padhang lan Gamelan | Aplikasi Umum Instrumen Medis, Tableware |

| No. BA (Anil Cerah) | 0.5mm ~ 2.0mm | Perawatan panas padhang sawise rolling kadhemen | Perkakas pawon, peralatan pawon, tujuan arsitektur |

| No. 4 | 0.4mm ~ 3.0mm | Polishing karo No.. 150 kanggo No.180 bolong abrasives. Rampung sing paling populer | Fasilitas Pengolahan Susu & Pangan, Peralatan Rumah Sakit, Bath-tub |

| No. 8 | 0.5mm ~ 2.0mm | Lumahing reflektif kaya pangilon kanthi polishing nganggo abrasive sing luwih apik luwih saka 800 bolong | Reflektor, Pangilon, Dekorasi Interior-Eksterior kanggo bangunan |

| HL (Garis Rambut) | 0.4mm ~ 3.0mm | Rampung kanthi polishing linier terus | Tujuan arsitektur, eskalator, kendaraan pawon |

Komposisi kimia

| sasmita | C | Si | Mn | P | S | Cr | Ni | Mo | Ti | N | Cu | Nb |

| 201 | ≤0.15 | ≤1.0 | 5.50-7.50 | ≤0.05 | ≤0.03 | 16.00-18.00 | 3.50-5.50 | - | - | 0.05-0.25 | - | - |

| 202 | ≤0.15 | ≤1.0 | 7.50-10.00 | ≤0.05 | ≤0.03 | 17.00-19.00 | 4.00-6.00 | - | - | 0.05-0.25 | - | - |

| 301 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0,045 | ≤0.03 | 16.00-18.00 | 6.00-8.00 | - | - | ≤0.1 | - | - |

| 302 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 17.00-19.00 | 8.00-10.00 | - | - | ≤0.1 | - | - |

| 303 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.2 | ≥0.15 | 17.00-19.00 | 8.00-10.00 | ≤0.6 | - | ≤0.1 | - | - |

| 304 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 17.00-19.00 | 8.00-10.00 | - | - | - | - | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 18.00-20.00 | 8.00-10.00 | - | - | - | - | - |

| 304H | 0.04-0.1 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 18.00-20.00 | 8.00-10.00 | - | - | - | - | - |

| 304N | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 18.00-20.00 | 8.00-10.00 | - | - | 0.10-0.16 | - | - |

| 304J1 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 18.00-20.00 | 6.00-9.00 | - | - | - | 1.00-3.00 | - |

| 305 | ≤0.12 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 17.00-19.00 | 10.50-13.00 | - | - | - | - | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 22.00-24.00 | 12.00-15.00 | - | - | - | - | - |

| 310S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 24.00-26.00 | 19.00-22.00 | - | - | - | - | - |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | - | - | - | - |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | 12.00-15.00 | 2.00-3.00 | - | - | - | - |

| 316H | ≤0.1 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | - | - | - | - |

| 316N | ≤0.03 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | - | 0.10-0.16 | - | - |

| 316Ti | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 16.00-19.00 | 11.00-14.00 | 2.00-3.00 | ≥5C | - | - | - |

| 317L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | 3.00-4.00 | - | - | - | - |

| 321 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 17.00-19.00 | 9.00-12.00 | - | 5C-0.7 | - | - | - |

| 347 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 17.00-19.00 | 9.00-12.00 | - | - | - | - | 10C-1.10 |

| 347H | ≤0.1 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 17.00-19.00 | 9.00-12.00 | - | - | - | - | 8C-1.10 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0,035 | ≤0.03 | 21.00-24.00 | 4.50-6.50 | 2.50-3.50 | - | 0.08-0.20 | - | - |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0,035 | ≤0.02 | 24.00-26.00 | 6.00-8.00 | 3.00-5.00 | - | 0.24-0.32 | - | - |

| 904L | ≤0.02 | ≤1.0 | ≤2.0 | ≤0,045 | ≤0.03 | 19.00-23.00 | 23.00-28.00 | 4.00-5.00 | - | - | 1.00-2.00 | - |

| C276 | ≤0.02 | ≤0.05 | ≤1.0 | - | - | 14.00-16.50 | Liyane | - | - | - | - | - |

| Monel400 | ≤0.3 | ≤0.5 | ≤2.0 | - | ≤0,024 | - | ≥63 | - | - | - | 28-34 | - |

| 409L | ≤0.03 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 17.00-19.00 | - | - | - | - | - | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 11.50-13.50 | - | - | - | - | - | - |

| 410L | ≤0.03 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 11.50-13.50 | - | - | - | - | - | - |

| 420J1 | 0.16-0.25 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 12.00-14.00 | - | - | - | - | - | - |

| 420J2 | 0.26-0.40 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 12.00-14.00 | - | - | - | - | - | - |

| 430 | ≤0.12 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | - | - | - | - | - | - |

| 436L | ≤0,025 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 16.00-19.00 | - | - | - | - | - | - |

| 439 | ≤0.03 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | - | - | - | - | - | - |

| 440A | 0.60-0.75 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | - | ≤0,75 | - | - | - | - |

| 440B | 0.75-0.95 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | - | ≤0,75 | - | - | - | - |

| 440C | 0.95-1.2 | ≤1.0 | ≤1.0 | ≤0,035 | ≤0.03 | 16.00-18.00 | - | ≤0,75 | - | - | - | - |

| 441 | ≤0.03 | 0.2-0.8 | ≤0.7 | ≤0.03 | ≤0,015 | 17.50-18.50 | - | ≤0.5 | 0.1-0.5 | ≤0,025 | - | 0.3+3C-0.9 |

WeLebokake produk stainless steel karo kertas anti-karat lan dering baja kanggo nyegah karusakan.

Label identifikasi diwenehi tag miturut spesifikasi standar utawa instruksi pelanggan.

packing khusus kasedhiya minangka saben requirement customer kang.

Paket Coil Stainless Steel

Paket Lembaran Stainless Steel / Plat Stainless Steel

Paket Strip Stainless Steel

Paket Pengiriman

Perusahaan kita adhedhasar ing Wuxi, ngumpulake kutha stainless steel industri ing China.

We specialized ing kumparan stainless, sheets lan piring, pipa stainless steel lan fittings, tabung stainless steel, lan uga produk aluminium lan produk tembaga.

Produk kita wis dipuji dening para klien saka Eropa, Amerika, Timur Tengah, Afrika lan Asia Tenggara. Kita bakal kurban produk competitive lan layanan lengkap kanggo pelanggan.

Kelas Baja Tahan Karat: 201, 202, 202cu, 204, 204cu, 303, 304, 304L, 308, 308L, 309, 309s, 310, 310s, 316, 316L, 43, 4, 4, 4, 4, 4, 4 30F, 440, 440c,

Kelas Paduan: Monel, Inconel, Hastolley, Duplex, Super Duplex, Titanium, Tantalum, Baja Kecepatan Tinggi, Baja Ringan, Aluminium, Baja Paduan, Baja Karbon, Paduan Nikel Khusus

Ing wangun: Bar Bulat, Bar Square, Bar Heksagonal, Bar Datar, Sudut, Saluran, Profil, Kabel, Wire Rod, Sheets, Plate, Pipa Seamless, ERW Pipes, Flanges, Fittings, etc.

Q1: Apa stainless?

A: Stainless tegese ora ana tandha ing lumahing baja, utawa jenis baja sing ora rusak dening udhara utawa banyu lan sing ora ngganti werna, spotless, tahan kanggo pawernan, rusting, efek korosif saka bahan kimia.

Q2: Apa stainless tegese ora karat?

A: Ora, stainless tegese ora gampang diwarnai utawa karat, nduweni kemampuan khusus kanggo nglawan pewarnaan, karat lan karat.

Q3: Apa sampeyan nyedhiyakake lembaran baja tahan karat?

A: Ya, kita nyedhiyakake macem-macem jinis lembaran stainless steel, kanthi kekandelan saka 0.3-3.0mm. lan ing macem-macem Rampung.

Q4: Apa sampeyan nampa layanan sing dipotong nganti dawa?

A: Mesthi, kepuasan pelanggan minangka prioritas utama.

Q5: Yen aku duwe pesenan cilik, apa sampeyan nampa pesenan cilik?

A: Ora masalah, keprihatinan sampeyan minangka keprihatinan kita, jumlah cilik ditampa.

Q6: Kepiye sampeyan bisa njamin kualitas produk sampeyan?

A: Pisanan, wiwit wiwitan, kita wis ngetrapake semangat ing pikirane, yaiku kualitas urip, para pekerja lan staf profesional bakal ngetutake saben langkah nganti barang kasebut dikemas kanthi apik lan dikirim.

Q7: Apa sampeyan bakal ngemas produk?

A: Wong profesional nindakake pengepakan profesional, kita duwe macem-macem jinis kemasan opsional kanggo pelanggan, ekonomi utawa luwih apik.

Q8: Apa sampeyan kudu ngerti saka customer sadurunge kutipan akurat?

A: Kanggo kutipan sing akurat, kita kudu ngerti kelas, kekandelan, ukuran, permukaan finish, warna lan jumlah pesenan, lan uga tujuan barang. Informasi produk sing disesuaikan bakal dibutuhake luwih akeh, kayata gambar, tata letak lan rencana. Banjur kita bakal nawakake penawaran kompetitif kanthi informasi ing ndhuwur.

Q9: Apa jenis istilah pembayaran sampeyan accpet?

A: Kita nampa T/T, West union, L/C.

Q10: Yen iki pesenan cilik, sampeyan bakal ngirim barang menyang agen kita?

A: Ya, kita lair kanggo ngatasi masalah pelanggan, kita bakal entuk barang kanthi aman menyang gudang agen lan ngirim gambar.

Q11: Apa sampeyan mung nggawe flat sheet? Aku pengin nggawe fabrikasi kanggo proyek anyarku.

A: Ora, kita utamané gawé stainless steel flat sheet perawatan lumahing, ing wektu sing padha, kita Pabrik selaras logam rampung produk minangka saben gambar lan rencana pelanggan, teknisi kita bakal ngurus liyane.

Q12: Pira negara sing wis diekspor?

A: Diekspor menyang luwih saka 50 negara utamane saka Amerika, Rusia, Inggris, Kuwait, Mesir, Iran,

Turki, Yordania, lsp.

Q13: Kepiye carane bisa entuk sawetara conto?

A: Sampel cilik ing toko lan bisa menehi conto gratis. Catalgue kasedhiya, paling

pola kita duwe sampel siap ing saham. sampel Custom bakal njupuk bab 5-7days.

Q14: Apa pangiriman?

A: wektu pangiriman Sample supaya iku 5-7 dina. Pesenan kontainer kira-kira 15-20 dina.

Q15: Apa aplikasi babagan Produk sampeyan?

A: 1.elevator lawang / kabin utawa lan eskalator kang sisih-tembok.

2. Tembok cladding ing njero ruangan utawa ing njaba ruangan rapat / restoran.

3.Facade nalika cladding liwat soko, kaya kolom ing lobi.

4. Langit-langit ing supermarket. 5.Dekoratif ndudohke ing sawetara panggonan hiburan.

Q16: Suwene Sampeyan Bisa Njamin Produk Iki / Rampung?

A: Jaminan warna luwih saka 10 taun. Sertifikat kualitas bahan asli bisa

diwenehake.