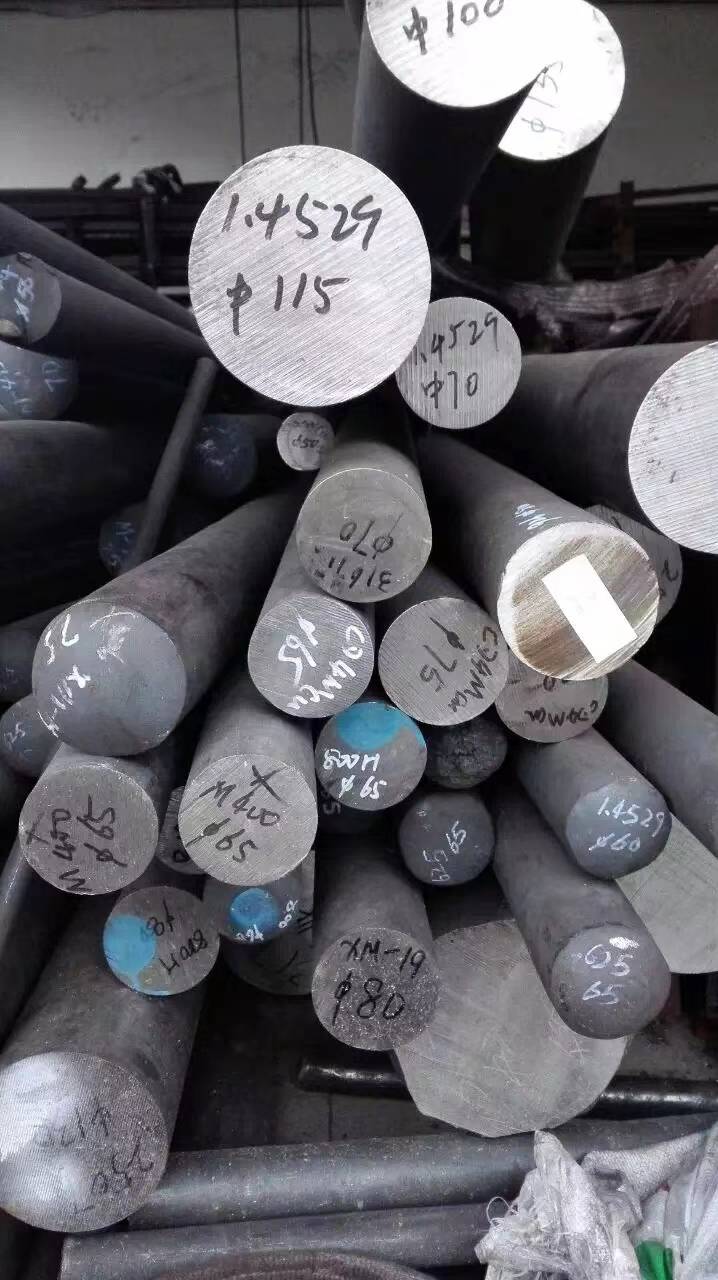

China Monel400 gburugburu Bar

Nkọwa dị mkpirikpi:

Ego 400bụ anickel-ọla kọpa alloy(ihe dịka 67% Ni - 23% Cu) nke na-eguzogide mmiri mmiri na uzuoku na okpomọkụ dị elu yana nnu na ngwọta caustic.Alloy 400bụ ihe ngwọta siri ike nke nwere ike ime ka ọ sie ike site na ịrụ ọrụ oyi. Alloy nickel a na-egosipụta njirimara dị ka ezigbo nguzogide corrosion, ezigbo weldability na ike dị elu. Ọnụ ọgụgụ corrosion dị ala na mmiri brackish ma ọ bụ oké osimiri na-agba ọsọ ọsọ na-ejikọta ya na nguzogide nrụgide-corrosion na-agbawa n'ọtụtụ mmiri dị ọhụrụ, na nkwụsị ya na ọnọdụ dị iche iche na-emebi emebi mere ka a na-eji ya eme ihe na ngwa mmiri na ihe ngwọta chloride ndị ọzọ na-adịghị oxidizing. Ngwakọta nickel a na-eguzogide ọgwụ hydrochloric na hydrofluoric acid mgbe a na-ekpochapụ ha. Dị ka a ga-atụ anya ya site na nnukwu ọla kọpa ya, nitric acid na amonia na-ebuso alloy 400 agha ngwa ngwa.

Ego 400nwere nnukwu ihe eji arụ ọrụ na okpomọkụ nke subzero, enwere ike iji ya na okpomọkụ ruo 1000 ° F, ebe agbaze ya bụ 2370-2460 ° F. Otú ọ dị, alloy 400 dị ala na ike na ọnọdụ annealed ya mere, ụdị iwe dị iche iche nwere ike ịdị. eji mee ka ike dịkwuo elu.

Ụdị dị

- Mpempe akwụkwọ

- Efere

- Ogwe

- Pipe & Tube (welded & enweghị nkebi)

- Ngwakọta (ya bụ flanges, slip-ons, blinds, weld-neck, lapjoints, long welding necks, socket weld, elbows, tees, stub-end, return, caps, crosses, reducers, and pipe nipples)

- Waya

Kedu ihe bụ njirimara nke Monel 400?

- Na-eguzogide mmiri mmiri na uzuoku na oke okpomọkụ

- Nnukwu iguzogide mmiri brackish ma ọ bụ mmiri oké osimiri na-asọ ọsọ ọsọ

- Nguzogide dị oke mma maka mgbawa corrosion nke nrụgide n'ọtụtụ mmiri dị ọhụrụ

- Karịsịa na-eguzogide hydrochloric na hydrofluoric acid mgbe a na-ekpochapụ ha

- Na-enye ụfọdụ iguzogide hydrochloric na sulfuric acid na obere okpomọkụ na mkpokọta, mana ọ na-adịkarịghị ihe nhọrọ maka acid ndị a.

- Ezigbo iguzogide nnu na-anọpụ iche na nnu alkaline

- Nguzogide chloride kpatara nrụgide corrosion mgbawa

- Ngwongwo arụrụ arụ dị mma sitere na okpomọkụ dị ala-efu ruo 1020F

- Nnukwu iguzogide alkalis

Ngwakọta kemịkalụ,%

| C | Mn | S | Si | Ni | Cu | Fe |

|---|---|---|---|---|---|---|

| .30 kacha | 2.00 kacha | .024 kacha | .50 kacha | 63.0 min | 28.0-34.0 | 2.50 kacha |

Monel na-eguzogide corrosion 400

Alloy 400 fọrọ nke nta ka ọ bụrụ ihe na-adịghị egbochi chloride ion stress corrosion na gburugburu ebe a na-ahụkarị. N'ozuzu, nguzogide corrosion ya dị ezigbo mma n'ibelata gburugburu ebe obibi, mana ọ dị njọ na ọnọdụ oxidizing. Ọ dịghị uru na oxidizing acid, dị ka nitric acid na nitrous. Ka o sina dị, ọ na-eguzogide ọtụtụ alkalis, nnu, mmiri, ngwaahịa nri, ihe ndị na-emepụta ihe na ọnọdụ ikuku na ọnọdụ okpomọkụ nkịtị na elu.

A na-awakpo alloy nickel a na gas na-ebu sọlfọ n'elu ihe dịka 700 ° F yana sọlfọ a wụrụ awụ na-awakpo alloy na okpomọkụ karịrị 500 ° F.

Monel 400 na-enye ihe dị ka nguzogide corrosion dị ka nickel mana ọ nwere oke nrụgide na-arụ ọrụ na okpomọkụ yana ọnụ ala dị ala n'ihi ike ya dị elu iji rụọ ọrụ.

N'ime ngwa ndị a na-eji Monel 400?

- Injinia mmiri

- Ngwá ọrụ nhazi kemịkalụ na hydrocarbon

- Mmanụ mmanụ na tankị mmiri ọhụrụ

- Ebe mmanụ ala dị nro

- Ndị na-ekpo ọkụ na-ekpochapụ ikuku

- Igwe ọkụ na-eri nri ndị na-ekpo ọkụ na mmiri na ihe ndị ọzọ na-ekpo ọkụ

- Valves, nfuli, aro, akwa akwa, na fasteners

- Ndị na-ekpo ọkụ ụlọ ọrụ

- Ihe mgbaze chlorinated

- Ụlọ elu distillation mmanụ crude

Mepụta ya na Monel 400

Alloy 400 nwere ike ịgbanye ngwa ngwa site na gas-tungsten arc, gas metal arc ma ọ bụ usoro arc a na-echebe site na iji ọla ncha kwesịrị ekwesị. Ọ dịghị mkpa maka ọgwụgwọ okpomọkụ nke weld post, Otú ọ dị, ihicha nke ọma mgbe ịgbado ọkụ gasịrị dị oké mkpa maka nguzogide corrosion kacha mma, ma ọ bụghị ya, enwere ike ibute mmetọ na embrittlement.

Enwere ike ịmepụta ihe ndị emechara na-emepụta ihe dị iche iche na-arụ ọrụ mgbe a na-eme njikwa kwesịrị ekwesị nke oke ọkụ ma ọ bụ oyi na-arụ ọrụ na nhọrọ nke ọgwụgwọ okpomọkụ kwesịrị ekwesị.

Dị ka ọtụtụ nickel alloys ndị ọzọ, Monel 400 na-esikarị ike na igwe ma na-arụsi ọrụ ike. Agbanyeghị, enwere ike nweta nsonaazụ mara mma ma ọ bụrụ na ị na-eme nhọrọ ziri ezi maka iji ngwaọrụ na igwe.

Ọkwa ihe

| Ihe onwunwe | ASTM A240 Standard | 201, 304 304L 304H 309S 309H 310S 310H 316 316H 316L 316Ti 317 317L 321 321H 347 347H 409 4104 410S |

| ASTM A480 ọkọlọtọ | 302, s30215, s30452, s30615, 308, 309, 309Cb, 310, 310Cb, S32615, S33228, S38100, 304H, 309H, 316H, 309H, 316H, 347H, 348H, S31060, N08811, N08020, N08367, N08810, N08904,N08926, S31277, S20161, S30600, S30601, S31254, S31266,S32050, S32654, S32053, S31727, S33251, S33251, S8 03, S32001, S32550, S31260, S32003, S32101, S32205, S32304, S32506, S32520, S32750, S32760, S32900, S32906, S32950, S32974 | |

| JIS 4304-2005 ọkọlọtọ | SUS301L, SUS301J1, SUS302, SUS304, SUS304L, SUS316/316L, SUS309S, SUS310S, 3SUS21L, SUS347, SUS410L, SUS430, SUS630 | |

| JIS G4305 ọkọlọtọ | SUS301, SUS301L, SUS301J1, SUS302B, SUS304, SUS304Cu, SUS304L, SUS304N1, SUS304N2, SUS304LN, SUS304J1, SUSJ2, SUS305, SUS301S, SUS301S 315J2, SUS316, SUS316L, SUS316N, SUS316LN, SUS316Ti, SUS316J1, SUS316J1L, SUS317, SUS317L, SUS317LN, SUS317J1, SUS317J2, SUS836L, SUS890L, SUS321, SUS347, SUSXM7, SUSXM15J1, SUS329J1, SUS329J3L, SUS40, SUS329J3L, SUS40 SUS430, SUS430LX, SUS430J1L, SUS434, SUS436L, SUS436J1L, SUS444, SUS445J1, SUS445J2, SUS447J1, SUSXM27, SUS403, SUS410, SUS410S, SUS420J1, SUS420J2, SUS440A |

Nkọwapụta ngwaahịa

| Mechaa | Ọkpụrụkpụ | Njirimara | Ngwa |

| Nke 1 | 3.0mm ~ 50.0mm | Emechara ya site na mkpọgharị ọkụ, mgbakasị ahụ na pickling, nke ejiri elu na-acha ọcha mara | Ngwá ọrụ ụlọ ọrụ kemịkalụ, tankị ụlọ ọrụ |

| Nọmba 2B | 0.3mm ~ 6.0mm | Emechara ya site na ọgwụgwọ okpomọkụ, pickling mgbe oyi na-atụgharị, na-esote ahịrị ngafe akpụkpọ ahụ ka ọ na-egbuke egbuke ma dịkwa larịị | Ngwa ngwa ahụike n'ozuzu, tebụl |

| Mba. BA (Bright Annealed) | 0.5mm ~ 2.0mm | ọgwụgwọ okpomọkụ na-egbuke egbuke mgbe oyi na-atụgharị | Ngwa kichin, ngwa kichin, ebumnuche ụlọ |

| Nke 4 | 0.4mm ~ 3.0mm | Ntugharị na nọmba 150 ruo No.180 mesh abrasives. Emecha kacha ewu ewu | Ebe a na-edozi mmiri ara ehi & nri, akụrụngwa ụlọ ọgwụ, ebe ịsa ahụ |

| Nke 8 | 0.5mm ~ 2.0mm | Elu na-egosipụta enyo dị ka enyo site na iji abrasives ndị mara mma na-ekpocha ihe karịrị ntupu 800 | Reflector, mirror, Ime-Mpụga mma maka ewu |

| HL (Ahịhịa ntutu) | 0.4mm ~ 3.0mm | Emechara ya site na polishing linear na-aga n'ihu | Ihe owuwu ihe owuwu, escalators, ụgbọ ala ngwa nri kichin |

Ngwakọta kemịkalụ

| Ọkwa | C | Si | Mn | P | S | Cr | Ni | Mo | Ti | N | Cu | Nb |

| 201 | ≤0.15 | ≤1.0 | 5.50-7.50 | ≤0.05 | ≤0.03 | 16.00-18.00 | 3.50-5.50 | - | - | 0.05-0.25 | - | - |

| 202 | ≤0.15 | ≤1.0 | 7.50-10.00 | ≤0.05 | ≤0.03 | 17.00-19.00 | 4.00-6.00 | - | - | 0.05-0.25 | - | - |

| 301 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 16.00-18.00 | 6.00-8.00 | - | - | ≤0.1 | - | - |

| 302 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 17.00-19.00 | 8.00-10.00 | - | - | ≤0.1 | - | - |

| 303 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.2 | ≥0.15 | 17.00-19.00 | 8.00-10.00 | ≤0.6 | - | ≤0.1 | - | - |

| 304 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 17.00-19.00 | 8.00-10.00 | - | - | - | - | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 18.00-20.00 | 8.00-10.00 | - | - | - | - | - |

| 304H | 0.04-0.1 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 18.00-20.00 | 8.00-10.00 | - | - | - | - | - |

| 304N | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 18.00-20.00 | 8.00-10.00 | - | - | 0.10-0.16 | - | - |

| 304J1 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 18.00-20.00 | 6.00-9.00 | - | - | - | 1.00-3.00 | - |

| 305 | ≤0.12 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 17.00-19.00 | 10.50-13.00 | - | - | - | - | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 22.00-24.00 | 12.00-15.00 | - | - | - | - | - |

| 310S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 24.00-26.00 | 19.00-22.00 | - | - | - | - | - |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | - | - | - | - |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | 12.00-15.00 | 2.00-3.00 | - | - | - | - |

| 316H | ≤0.1 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | - | - | - | - |

| 316N | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | - | 0.10-0.16 | - | - |

| 316 Ti | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 16.00-19.00 | 11.00-14.00 | 2.00-3.00 | ≥5C | - | - | - |

| 317L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | 3.00-4.00 | - | - | - | - |

| 321 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 17.00-19.00 | 9.00-12.00 | - | 5C-0.7 | - | - | - |

| 347 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 17.00-19.00 | 9.00-12.00 | - | - | - | - | 10C-1.10 |

| 347H | ≤0.1 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 17.00-19.00 | 9.00-12.00 | - | - | - | - | 8C-1.10 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 21.00-24.00 | 4.50-6.50 | 2.50-3.50 | - | 0.08-0.20 | - | - |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 24.00-26.00 | 6.00-8.00 | 3.00-5.00 | - | 0.24-0.32 | - | - |

| 904L | ≤0.02 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 19.00-23.00 | 23.00-28.00 | 4.00-5.00 | - | - | 1.00-2.00 | - |

| C276 | ≤0.02 | ≤0.05 | ≤1.0 | - | - | 14.00-16.50 | Ndị ọzọ | - | - | - | - | - |

| Ego 400 | ≤0.3 | ≤0.5 | ≤2.0 | - | ≤0.024 | - | ≥63 | - | - | - | 28-34 | - |

| 409L | ≤0.03 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 17.00-19.00 | - | - | - | - | - | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 11.50-13.50 | - | - | - | - | - | - |

| 410L | ≤0.03 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 11.50-13.50 | - | - | - | - | - | - |

| 420J1 | 0.16-0.25 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 12.00-14.00 | - | - | - | - | - | - |

| 420J2 | 0.26-0.40 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 12.00-14.00 | - | - | - | - | - | - |

| 430 | ≤0.12 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | - | - | - | - | - | - |

| 436L | ≤0.025 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 16.00-19.00 | - | - | - | - | - | - |

| 439 | ≤0.03 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | - | - | - | - | - | - |

| 440A | 0.60-0.75 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | - | ≤0.75 | - | - | - | - |

| 440B | 0.75-0.95 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | - | ≤0.75 | - | - | - | - |

| 440C | 0.95-1.2 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 16.00-18.00 | - | ≤0.75 | - | - | - | - |

| 441 | ≤0.03 | 0.2-0.8 | ≤0.7 | ≤0.03 | ≤0.015 | 17.50-18.50 | - | ≤0.5 | 0.1-0.5 | ≤0.025 | - | 0.3+ 3C-0.9 |

Anyịkechie ngwaahịa igwe anaghị agba nchara na akwụkwọ mgbochi nchara na mgbanaka ígwè iji gbochie mmebi.

A na-akpado akara njirimara dị ka ọkọlọtọ ọkọlọtọ ma ọ bụ ntuziaka ndị ahịa si dị.

Nkwakọ ngwaahịa pụrụ iche dị ka onye ahịa chọrọ.

ngwugwu igwe anaghị agba nchara

Mpempe mpempe akwụkwọ igwe anaghị agba nchara / igwe anaghị agba nchara

ngwugwu eriri igwe anaghị agba nchara

Ngwungwu Mbupu

Ụlọ ọrụ anyị dabeere na Wuxi, na-achịkọta obodo nke ụlọ ọrụ igwe anaghị agba nchara na China.

Anyị pụrụ iche na igwe anaghị agba nchara, mpempe akwụkwọ na efere, ọkpọkọ igwe anaghị agba nchara na akwa akwa, tubes igwe anaghị agba nchara, yana ngwaahịa aluminom na ngwaahịa ọla kọpa.

Ndị ahịa anyị sitere na Europe, America, Middle East, Africa na Southeast Asia toro ngwaahịa anyị nke ukwuu. Anyị ga-enye ndị ahịa ngwaahịa asọmpi na ọrụ zuru oke.

Ọkwa igwe anaghị agba nchara: 201, 202, 202cu, 204, 204cu, 303, 304, 304L, 308, 308L, 309, 309s, 310, 310s, 316, 316, 3, 3, 40 0, 430F, 440, 440c,

Alloy ọkwa:Monel, Inconel, Hastolley, Duplex, Super Duplex, Titanium, Tantalum, High Speed Steel, Dị nwayọọ Steel, Aluminium, Alloy Steel, Carbon Steel, Special Nickel Alloys

N'ụdị: Ogwe gburugburu, Ogwe Square, Ogwe Hexagonal, Ogwe Flat, Angle, Channels, Profiles, Wires, Wire Rods, Sheets, Plates, Seamless Pipes, ERW Pipes, Flanges, Fittings, etc.

Q1: Gịnị bụ igwe anaghị agba nchara?

A: Igwe anaghị agba nchara pụtara enweghị akara n'elu nchara, ma ọ bụ ụdị nchara nke ikuku ma ọ bụ mmiri na-emebighị na nke na-adịghị agbanwe agba, enweghị ntụpọ, na-eguzogide ọgwụ, nchara, mmetụta na-emebi emebi nke kemịkalụ.

Q2: Igwe anaghị agba nchara ọ pụtara enweghị nchara?

A: Mba, igwe anaghị agba nchara pụtara adịghị mfe ịnweta ntụpọ ma ọ bụ nchara, ọ nwere ikike pụrụ iche iji guzogide nsị, nchara na corrosion.

Q3: Ị na-enye mpempe akwụkwọ anaghị agba nchara?

A: Ee, anyị na-enye ụdị dị iche iche nke igwe anaghị agba nchara, na ọkpụrụkpụ ranges si 0.3-3.0mm. na n'ụdị dị iche iche.

Q4: Ị na-anabata ọrụ ịkpụ n'ogologo?

A: N'ezie, afọ ojuju ndị ahịa bụ ihe kacha anyị mkpa.

Q5: Ọ bụrụ na m nwere obere usoro, ị na-anabata obere usoro?

A: Ọ bụghị nsogbu, nchegbu gị bụ nchegbu anyị, a na-anabata obere obere.

Q6: Kedu ka ị ga-esi kwe nkwa ịdị mma ngwaahịa gị?

A: Nke mbụ, site na mmalite, anyị etinyelarị mmụọ n'uche ha, nke ahụ bụ àgwà bụ ndụ, ndị ọrụ ọkachamara anyị na ndị ọrụ ga-agbaso nzọụkwụ ọ bụla ruo mgbe ngwongwo ndị ahụ na-akwakọba nke ọma ma bupu ya.

Q7: Ị ga-akwakọba ngwaahịa?

A: Ndị ọkachamara na-eme nkwakọ ngwaahịa ọkachamara, anyị nwere ụdị nkwakọ ngwaahịa dị iche iche maka ndị ahịa, otu akụ na ụba ma ọ bụ ka mma.

Q8: Kedu ihe ị chọrọ ịma site n'aka ndị ahịa tupu nkwupụta ziri ezi?

A: Maka nkọwa ziri ezi, anyị kwesịrị ịma ọkwa, ọkpụrụkpụ, nha, imecha elu, agba na ọnụ ọgụgụ nke ihe ị chọrọ, yana ebe ị na-aga. A ga-achọkwu ozi ngwaahịa ahaziri ahazi, dị ka eserese, nhazi na atụmatụ. Mgbe ahụ, anyị ga-enye nhota asọmpi na ozi dị n'elu.

Q9: Kedu ụdị ụgwọ ịkwụ ụgwọ ị na-anabata?

A: Anyị na-anabata T/T, West union, L/C.

Q10: Ọ bụrụ na nke a bụ obere iwu, ị ga-ebugara ndị ọrụ anyị ngwongwo ndị ahụ?

A: Ee, a mụrụ anyị iji dozie nsogbu nke ndị ahịa anyị, anyị ga-enweta ngwongwo ahụ n'enweghị nsogbu na ụlọ nkwakọba ihe nke onye ọrụ gị ma ziga gị foto.

Q11: Ị na-eme mpempe akwụkwọ dị larịị? Achọrọ m ịmebe echiche maka ọrụ ọhụrụ m.

A: Ee e, anyị tumadi na-emepụta igwe anaghị agba nchara ewepụghị mpempe akwụkwọ n'elu ọgwụgwọ, n'otu oge ahụ, anyị rụpụta ahaziri metal okokụre ngwaahịa dị ka kwa ahịa ịbịaru na atụmatụ, anyị technician ga-elekọta ndị ọzọ.

Q12: Ugboro ole ka i bupuburu?

A: Ebupụ ya karịa mba 50 tumadi site na America, Russia, UK, Kuwait, Egypt, Iran,

Turkey, Jordan, wdg.

Q13: Kedu ka m ga-esi nweta ụfọdụ nlele?

A: Obere ihe nlele na-echekwa ma nwee ike ịnye ihe nlele n'efu. Catalgue dị, ọtụtụ

ụkpụrụ anyị nwere njikere samples na ngwaahịa. Ihe nlele ahaziri ahazi ga-ewe ihe dịka ụbọchị 5-7.

Q14: Gịnị bụ nnyefe?

A: Oge nnyefe nke ihe nlele bụ ụbọchị 5-7. Ngwunye akpa bụ ihe dịka ụbọchị 15-20.

Q15: Gịnị bụ ngwa gbasara ngwaahịa gị?

A: 1. elevator ọnụ ụzọ / ụlọ ma ọ bụ na escalator's n'akụkụ mgbidi.

2.Mgbidi mkpuchi n'ime ma ọ bụ n'èzí nzukọ ụlọ / ụlọ oriri na ọṅụṅụ.

3.Facade mgbe cladding n'elu ihe, dị ka ogidi na n'ọnụ ụlọ.

4.Ciling na nnukwu ụlọ ahịa. 5.Decorative adọta na ụfọdụ ntụrụndụ ebe.

Q16: Ogologo oge ole ka ị nwere ike ikwe nkwa maka ngwaahịa a / mechaa?

A: Agba nkwa maka ihe karịrị afọ 10. Asambodo ogo ihe izizi nwere ike

ka enyere.